Home / News

Home / News

Why Choose Our Colored Coating Engraving Tools?

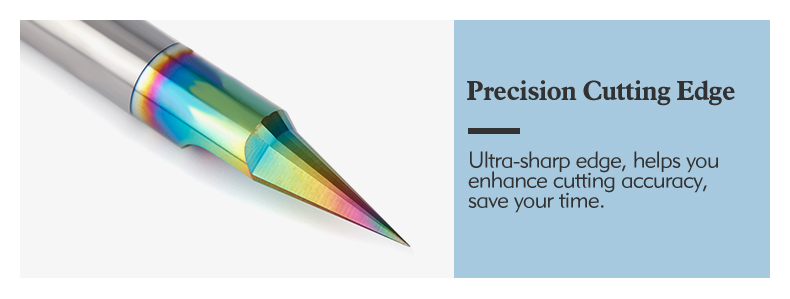

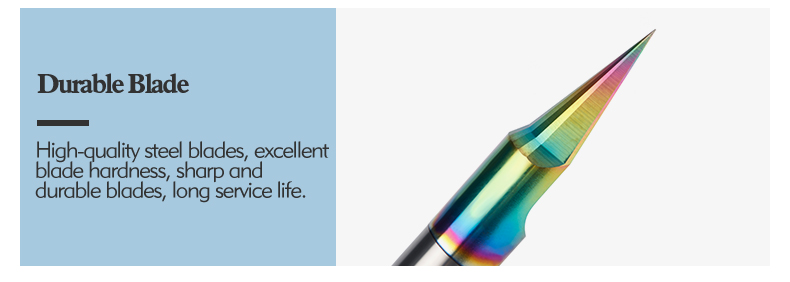

Unmatched Hardness & Durability: At the core lies high-grade tungsten carbide, renowned for its exceptional hardness and resistance to wear, ensuring your tools stay sharper for significantly longer than standard steel.

Vibrant & Resilient Color: The advanced PVD (Physical Vapor Deposition) coating bonds permanently to the tool surface. This isn't just paint; it's an ultra-hard, wear-resistant layer available in a spectrum of vivid, consistent colors (e.g., Sapphire Blue, Crimson Red, Emerald Green, Onyx Black, Titanium Gold).

Enhanced Corrosion Resistance: The colored coating provides an additional protective barrier, shielding the tungsten steel beneath from moisture, acids, and oxidation, extending the tool's overall lifespan even in demanding workshop environments.

Reduced Glare & Eye Comfort: The matte or satin finish of the coating significantly reduces light reflection compared to bare metal, minimizing eye strain during intricate, focused work sessions.

Instant Tool Identification: Never fumble for the right tool again! The distinct colors allow for immediate visual identification of different tip shapes, sizes, or personal sets, streamlining your workflow and boosting efficiency. Organize your toolkit with ease.

View More(Total0)Comment Lists