Product Overview

Engineered with precision and durability in mind, this tungsten carbide milling tool is designed for roughing applications across diverse industries, from automotive to aerospace. With ISO TUV certification, a 99.5% customer satisfaction rate, and advanced production facilities (TTB/ANCA/DECKEL/HOYMAN/TOP machines), it delivers exceptional performance on aluminum, high-hardness steel, plastic, and composite materials. Whether you’re seeking faster chip evacuation, enhanced cutting speed, or tailored solutions, this high-efficiency roughing cutter meets the demands of modern machining.

Key Features & Benefits

Optimized 3-Flute Design for Peak Efficiency

Faster Chip Evacuation & Reduced Cutting Force

The 3-flute design features wider flute channels, enabling rapid chip evacuation—critical for preventing chip clogging during high-speed roughing. This design also reduces cutting force, minimizing workpiece deformation and extending tool life, especially when machining soft metals like aluminum or high-tensile steel.

Enhanced Cutting Speed for Mass Production

With fewer flutes than traditional 4-flute cutters, the 3-flute design reduces contact resistance, allowing higher spindle speeds and feed rates. This translates to faster machining cycles, making it ideal for mass production environments where productivity is key.

Superior Tungsten Carbide Grain Structure

Ultra-Fine Grain Size (0.4-0.6μm)

Crafted from premium solid carbide with ultra-fine grain sizes (0.4-0.6μm) and high cobalt content (10-12%), the cutter offers exceptional flexural strength (4200-4500N/mm²). This micro-grain structure enhances edge retention, resists wear, and ensures consistent performance even under heavy loads.

HRC Compatibility (45-68HRC)

Optimized for machining materials with hardness ranging from 45HRC to 68HRC, the cutter handles high-hardness steel, tool steel, and alloy steel with ease. Eliminating the need for multiple tools for different workpieces.

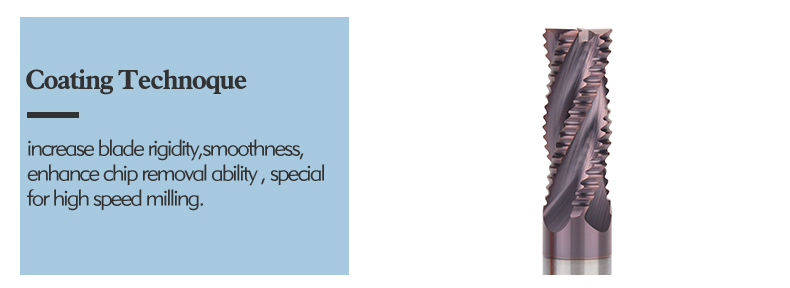

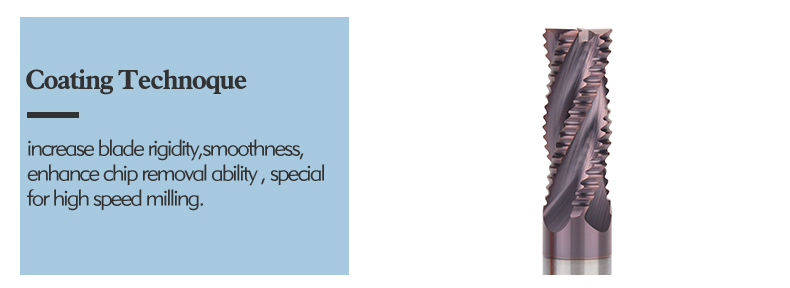

Specialized Coating for Diverse Applications

Diamond Coating for Abrasive Materials

The optional Diamond coating provides extreme hardness (up to 8000HV) and wear resistance, making it perfect for machining abrasive materials like carbon fiber, fiberglass, and reinforced plastics. It also reduces friction and heat, ensuring smooth cutting even at high speeds.

TiSiN Coating for High-Speed Dry Cutting

For high-speed dry cutting applications, the TiSiN coating (4300HV hardness, 1000°C oxidation temperature) offers excellent heat stability and low friction. It’s ideal for machining mould steel, stainless steel, and other high-hardness metals without coolant.

Precision Engineering for Stability

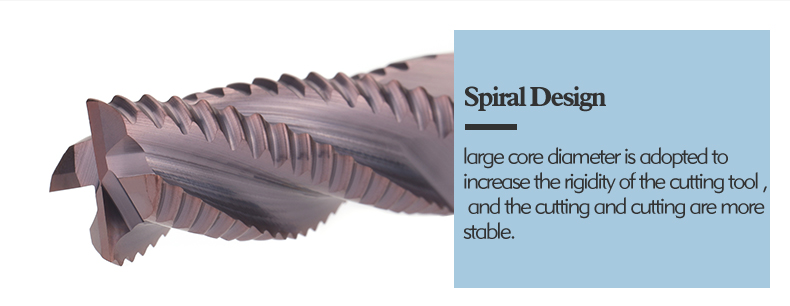

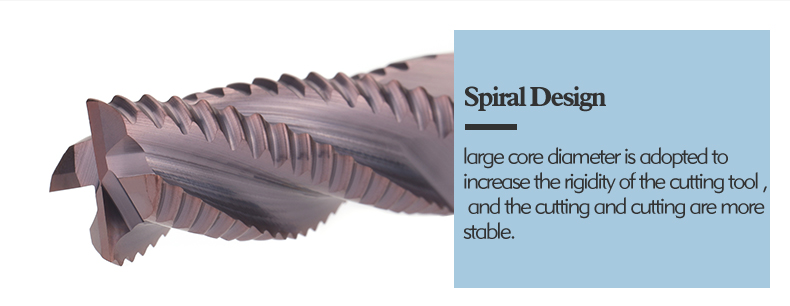

Spiral Flute Geometry

A precision spiral flute geometry (30° helix angle) ensures optimal chip flow and cutting stability, reducing vibration and improving surface finish. This design also enhances tool rigidity, preventing deflection during deep cuts.

Product Specifications

Core Specifications

Parameter | Details |

Product Name | BFL 3-Flute Solid Carbide Roughing End Mill |

Material | Ultra-Fine Grain Tungsten Carbide (Custom Grades Available) |

HRC Range | 45HRC – 68HRC |

Flute Count | 3 Flutes |

Coating Types | TiAlN, TiSiN, Naco, Diamond, DLC |

Certification | ISO TUV |

Suitable Materials | Aluminum, high-hardness steel, tool steel, alloy steel, plastic, composite materials |

Dimension Options

Blade Diameter (mm) | Blade Length (mm) | Shank Diameter (mm) | Full Length (mm) |

5.0 | 10 | 12 | 60 |

7.0 | 12 | 16 | 70 |

9.0 | 15 | 20 | 80 |

11.0 | 18 | 25 | 90 |

13.0 | 20 | 30 | 100 |

15.0 | 22 | 35 | 110 |

Custom Sizes | Available (3-25mm diameter, 50-120mm full length) |

BFL OEM & Customization Services

Comprehensive Customization Support

BFL’s verified customization capabilities cater to unique business needs, offering flexible solutions for logo, packaging, parameters, and design.

Logo, Graphic & Parameter Customization

Services: Laser marking (logo, specifications, brand name), graphic customization (product labels, user guides)

Customizable Parameters: Blade diameter, length, helix angle, HRC grade, coating type

MO10 pieces for logo/graphic customization; Negotiable for parameter adjustments

Bespoke Packaging Solutions

Options: Custom outer boxes, branded packaging tubes, eco-friendly packaging

Add-Ons: Customized labels with product details, company information, or barcodes

MO10 pieces

Sample-Based & Drawing-Based Customization

Support: Provide samples or technical drawings for full customization

Lead Time: 7-15 days for sample production; Negotiable for bulk orders

Quality Assurance: Strict quality inspection for customized products (ISO TUV certified)

FAQ

What advantages does a 3-flute end mill have over a 4-flute cutter?

The 3-flute solid carbide end mill offers faster chip evacuation (wider flute channels) and higher cutting speeds (reduced contact resistance). It’s ideal for soft metals (aluminum) and high-volume production, as it minimizes clogging and improves efficiency. 4-flute cutters excel in precision finishing, while 3-flute cutters prioritize roughing speed.

Can I customize the blade diameter and length beyond the standard range?

Yes, BFL supports custom sizes (3-25mm diameter, 50-120mm full length). Provide your technical drawings or sample, and our engineering team will develop a tailored solution. The MOQ for custom sizes is negotiable based on your order volume.

Which shipping methods are available, and how long does delivery take?

BFL offers global shipping via UPS, Fedex, DHL, TNT, EMS, or sea freight. Delivery times vary by region: 3-7 days for express (UPS/Fedex/DHL), 15-30 days for sea freight. We also provide tracking information for all orders.

Is this cutter suitable for aluminum machining?

Absolutely! The 3-flute design and wide flute channels make it perfect for aluminum machining. It prevents chip clogging and reduces cutting force, ensuring smooth, fast roughing. For optimal results, we recommend the TiAlN or Diamond coating.

What quality control processes does BFL implement?

BFL adheres to ISO TUV standards, with strict quality inspection at every production stage: raw material testing, machining precision checks, coating quality verification, and final performance testing. We also offer a 99.5% customer satisfaction rate, backed by positive reviews from global clients.

English

English