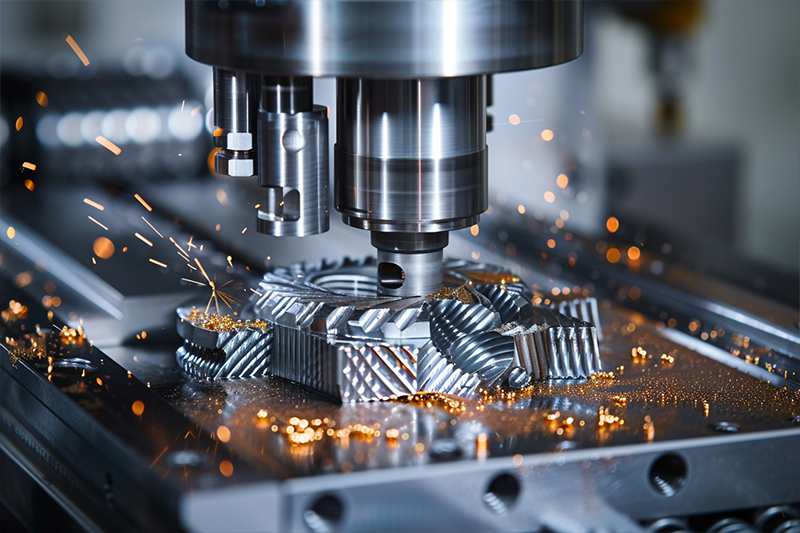

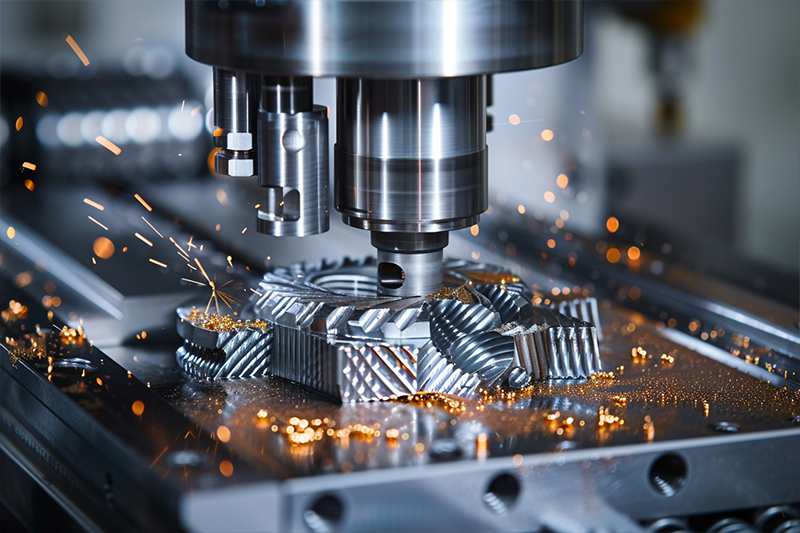

In heavy-duty cutting scenarios for energy equipment (such as wind power gears and nuclear power pump bodies), the double-edged drill bit, with its high wear resistance and impact resistance, meets the challenges of large cutting volumes and high-hardness workpieces (HRC50+). The double-edged struct

Read More

For the mold industry's need for complex surface contour milling, the company provides non-standard customized double-edged end mill solutions. The double-edged design enhances cutting stability through the support of the two cutting edges, reducing the impact of vibration on complex contour machini

Read More

In mass production scenarios of automotive parts, the double-edged drill bit, combined with a collet chuck and high-speed CNC machine tools, achieves efficient and stable processing of end milling, grooving, and other processes. The double-edged structure enhances the support and guidance of the dri

Read More

For the drilling and milling needs of high-hardness alloys (such as titanium alloys and superalloys) in the aerospace field, the company utilizes a double-edged drill bit combined with customized end mills and solid carbide solutions. The double-edged design, through the support and guidance of the

Read More  English

English