Product Overview

Manufactured by Changzhou North Carbide Tool Co., Ltd.—a trusted OEM supplier with 17 years of expertise—this finishing milling cutter features a 6-flute design, negative front angle, and 45-degree helix angle, delivering burr-free, glossy surface finishes. Crafted from 100% new solid carbide, it supports HRC ratings from 45 to 65 and offers multi-coating options (AlTiN, TiSiN, DLC, Nano) for versatility. Ideal for CNC machining centers, it excels in processing alloy steel, carbon steel, die steel, and pre-hardened mold steel, with OEM customization available to fit specific production needs. With 94% customer satisfaction and on-time shipment ratings of 4.9/5, this high rigidity end mill is a reliable choice for industrial finishing applications.

Key Features & Benefits

6-Flute Design for Superior Finishing Results

The 6-flute configuration increases cutting contact area, reducing workpiece vibration and delivering ultra-smooth, burr-free surfaces. Perfect for finishing operations, it eliminates the need for secondary polishing, saving time and labor costs.

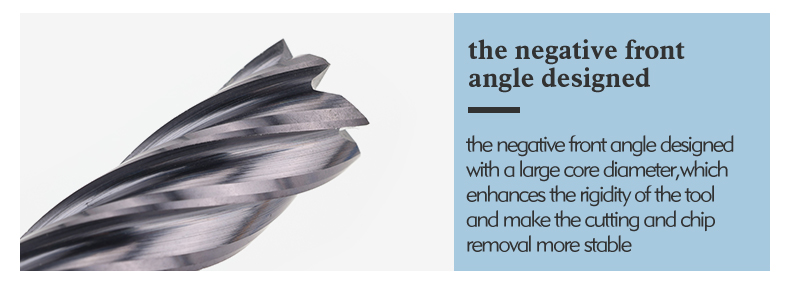

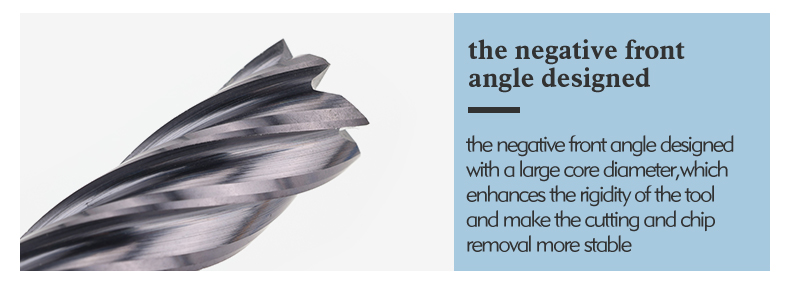

Negative Front Angle & Large Core Diameter

Engineered with a negative front angle and large core diameter, the endmill boasts exceptional high rigidity, minimizing tool deflection during high-speed cutting. This design ensures stable chip removal and consistent performance, even with hard materials up to 65HRC.

Double-Edged Belt for High-Speed Cutting

The double-edged belt design prevents tool sticking and reduces burr formation, enabling high-speed cutting without compromising surface quality. It enhances cutting efficiency and extends tool life, ideal for high-volume production.

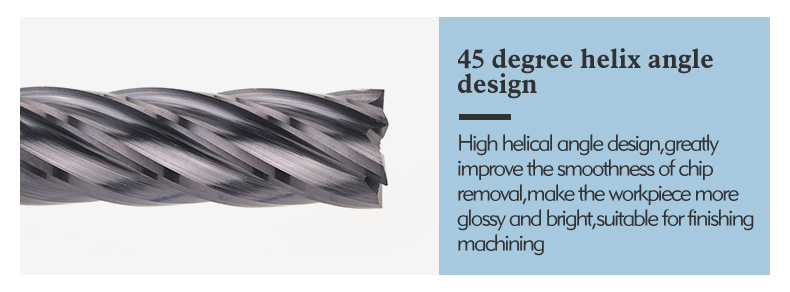

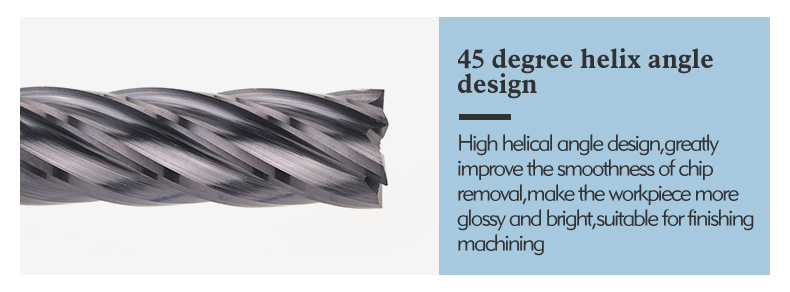

45-Degree Helix Angle for Smooth Chip Flow

The 45-degree helix angle optimizes chip evacuation, preventing clogging and heat buildup. This ensures continuous, efficient cutting and maintains the cutter’s sharpness, even during prolonged use.

Passivation Treatment for Durability

Post-manufacturing passivation treatment reduces tiny gaps on the blade edge, preventing chipping and enhancing wear resistance. This process extends tool life and ensures consistent performance across tough machining tasks.

Product Specifications

Parameter | Details |

Product Name | BFL 6-Flute Tungsten Carbide Finishing End Mill |

Material | 100% Solid Carbide (Tungsten Carbide) |

Coating | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO |

HRC Rating | 45/55/60/65 Degree |

Flute Quantity | 6 Flutes (2-6 Flutes Customizable) |

Helix Angle | 45 Degree |

Shank Diameter (d) | 6-25mm |

Cutting Diameter (D) | 6-25mm |

Cutting Length (l) | 15-40mm |

Overall Length (L) | 50-100mm |

Applicable Materials | Alloy Steel, Carbon Steel, Stainless Steel, Die Steel, Pre-hardened Mold Steel |

Manufacturing Equipment | TTB/ANCA/DECKEL/HOYMAN/TOP |

Project code | D | d

| l | L |

BFL-EMD-060 | 6.0 | 6 | 15 | 50 |

BFL-EMD-080 | 8.0 | 8 | 20 | 60 |

BFL-EMD-100 | 10.00 | 10 | 25 | 75 |

BFL-EMD-120 | 12.00 | 12 | 30 | 75 |

BFL-EMD-160 | 16.00 | 16 | 40 | 100 |

BFL-EMD-200 | 20.00 | 20 | 40 | 100 |

BFL-EMD-250 | 25.00 | 25 | 40 | 100 |

BFL OEM & Customization Services

BFL’s flexible customization capabilities cater to unique business needs, with verified support for minor, drawing-based, sample-based, and full customization:

Free Laser Marking: Add LOGO, specifications, or parameters to the cutter body at no extra cost.

Custom Label Design: Personalize labels with brand messaging or product details.

Tailored Packaging: Choose custom outer boxes or optional packaging tubes for safe transport.

Coating Customization: Select from AlTiN, TiSiN, DLC, or NANO coatings to match application requirements.

Flute Quantity Adjustment: Customize flute count from 2 to 6 flutes for specific cutting needs.

FAQ

What makes this endmill suitable for finishing applications?

The 6-flute design, 45-degree helix angle, and passivation treatment deliver burr-free finishing with glossy surface quality, eliminating the need for secondary processing.

What is the lead time for small orders?

For 1-10 pieces, lead time is 7 days; bulk orders (>10 pieces) are negotiable based on quantity and customization needs.

Can I customize the shank diameter?

Yes! Shank diameter is customizable from 4-20mm to fit your machining equipment.

English

English