BFL 2-Flute Uncoated Flat End Mill | In Stock & Ready to Ship

Standard 2-flute flat end mill with uncoated finish, ideal for general-purpose CNC milling.

Available in a full range of common sizes to meet your everyday machining needs — efficient, reliable, and hassle-free.

Product Parameters

Specification | Details |

Product Name | BFL Solid Carbide 2-Flute Uncoated Flat End Mill |

Material | High-Grade Solid Tungsten Carbide |

Flute Count | 2 Flutes |

Hardness (HRC) | Versatile options for 45, 55, 60, and 65 HRC applications |

Precision | High Precision |

Machine Compatibility | CNC Machining Centers & Milling Machines |

Recommended Usage | General and high-speed metal milling |

Processing Type | Metal |

Coating | Uncoated (Other coatings are available for customization.) |

Place of Origin | Jiangsu, China |

Model Number | Standard Size |

Brand | BFL |

| Customization Support | OEM |

| HRC | 55 (45/60/65 optional) |

| Flute | 2 Flutes |

| Tolerance | +-5um |

| Coating | Uncoated (AlALN /Altin, Tialn, Tisin, Tin, DLc,Nano, Diamond optional) |

| Suitable For | Copper,Cast iron,Carbon Steel,Mould steel processing etc. |

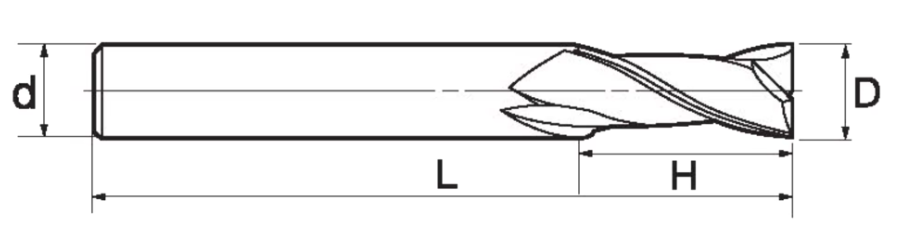

| item code | Outside Diameter

(D) | Shank Diameter

(d) | Flute Length

(I) | Overall Length

(L) |

| BFL-ED-010 | 1.0 | 4 | 3 | 50 |

| BFL-ED-015 | 1.5 | 4 | 4 | 50 |

| BFL-ED-020 | 2.0 | 4 | 6 | 50 |

| BFL-ED-025 | 2.5 | 4 | 8 | 50 |

| BFL-ED-030 | 3.0 | 3 | 8 | 50 |

| BFL-ED-031 | 3.0 | 4 | 8 | 50 |

| BFL-ED-035 | 3.5 | 4 | 11 | 50 |

| BFL-ED-040 | 4.0 | 4 | 11 | 50 |

| BFL-ED-610 | 1.0 | 6 | 3 | 50 |

| BFL-ED-615 | 1.5 | 6 | 4 | 50 |

| BFL-ED-620 | 2.0 | 6 | 6 | 50 |

| BFL-ED-625 | 2.5 | 6 | 8 | 50 |

| BFL-ED-630 | 3.0 | 6 | 8 | 50 |

| BFL-ED-635 | 3.5 | 6 | 11 | 50 |

| BFL-ED-640 | 4.0 | 6 | 11 | 50 |

| BFL-ED-645 | 4.5 | 6 | 13 | 50 |

| BFL-ED-650 | 5.0 | 5 | 13 | 50 |

| BFL-ED-651 | 5.0 | 6 | 13 | 50 |

| BFL-ED-660 | 6.0 | 6 | 15 | 50 |

| BFL-ED-070 | 7.0 | 8 | 20 | 60 |

| BFL-ED-080 | 8.0 | 8 | 20 | 60 |

| BFL-ED-090 | 9.0 | 10 | 25 | 75 |

| BFL-ED-100 | 10.0 | 10 | 25 | 75 |

| BFL-ED-120 | 12.0 | 12 | 30 | 75 |

| BFL-ED-140 | 14.0 | 14 | 45 | 100 |

| BFL-ED-160 | 16.0 | 16 | 45 | 100 |

| BFL-ED-180 | 18.0 | 18 | 45 | 100 |

| BFL-ED-200 | 20.0 | 20 | 45 | 100 |

4 Stage Cutting Tool Inspection to Ensure Quality

(1) During production, the Helicheck PlusWalter device is used for first-piece, last-piece, and random sampling inspections to comprehensively check helix angle, peripheral edge clearance angle, tip rake angle, tip clearance angle, R-value, profile, and form cutters.

(2) After production, a full inspection is conducted using a 2D measuring instrument or microscope, checking tooth count, outer diameter, flute length, core diameter, helix angle, clearance width, tip eccentricity and center, tip face flatness, runout, and presence of notches or serrations.

(3) Pre-coating inspection using a 2D measuring instrument.

(4) Post-coating comprehensive inspection using a 2D measuring instrument.

BFL OEM & Customization Services

FAQ

1. Are you manufacturer? Do you have factory?

We are professional manufacturer,have more than 15 years experience in this field.

2. Is free shipping possible?

We don't offer free shipping service,but we will give you some discount if you buy large quantity products. And we have cooperation Express Companies,can offer you the best price of shipping cost.

3. Can you send products to our Forwarder in China?

Yes,if you have Forwarder in China,we will glad to send products to him/her.

4. Can you produce Special carbide Tools ?

Yes We can. From 2013 year. Our factory main market change from standard end mills to special tools. Special tools according to your drawing and sample.

English

English