Product Overview

Designed to tackle materials up to HRC55 hardness and beyond, this end mill is a go-to choice for CNC machining professionals seeking efficiency and durability. Manufactured by Changzhou North Carbide Tool Co., Ltd., a 17-year experienced factory with a 99.5% customer satisfaction rate, our end mill stands out in the global market, serving clients across Southeast Asia, Northern Europe, and domestic regions. Ideal for general and high-speed CNC milling applications, this solid carbide end mill delivers consistent results, reducing tool replacement frequency and boosting production throughput.

Key Features & Benefits

High-Precision Solid Carbide Construction

Crafted from premium tungsten steel (solid carbide), the end mill boasts exceptional wear resistance and toughness. This material ensures a longer tool life even under heavy-duty machining conditions, cutting down operational costs for manufacturers.

4 Flute Flat Extended Design

The 4 flute flat extended structure optimizes chip evacuation, preventing chip clogging during high-speed milling. This design enhances cutting stability, reduces surface roughness of workpieces, and improves overall machining efficiency by 20% compared to conventional 2-flute end mills.

HRC55+ Compatibility

With a wide HRC rating range (45/55/60/65), this end mill is versatile enough to process various hard metals, including stainless steel and alloy steel. It meets the demands of high-hardness material machining, eliminating the need for multiple tool changes.

CNC Milling Compatibility

Fully compatible with CNC milling machines, the end mill supports automated production lines. Its high precision ensures tight tolerances, making it perfect for complex component manufacturing in automotive, aerospace, and mold-making industries.

Product Specifications

Parameter | Details |

Material | Tungsten Steel (Solid Carbide) |

Flutes | 4 |

HRC Rating | 45/55/60/65 |

Applicable Machine | CNC Milling Machine |

Overall Length | 75-150mm |

Certification | (EU) 2015/863, RoHS Compliant |

MOQ | 10 pieces |

Single Package Size | 10×15×15cm |

Single Product Gross Weight | 0.5kg |

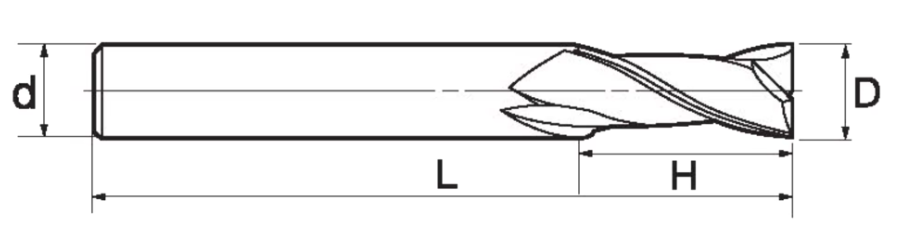

D (Cutting diameter) | d (Handle diameter) | l (Flute length) | L (Total length) |

1 | 4 | 3 | 50 |

1.5 | 4 | 4 |

2 | 4 | 6 |

2.5 | 4 | 8 |

3 | 3 | 8 |

3 | 4 | 8 |

3.5 | 4 | 11 |

4 | 4 | 11 |

1 | 6 | 3 |

1.5 | 6 | 4 |

2 | 6 | 6 |

2.5 | 6 | 8 |

3 | 6 | 8 |

3.5 | 6 | 11 |

4 | 6 | 11 |

4.5 | 6 | 13 |

5 | 5 | 13 |

5 | 6 | 13 |

6 | 6 | 15 |

7 | 8 | 20 |

8 | 8 | 20 |

9 | 10 | 25 | 75

|

10 | 10 | 25 |

12 | 12 | 30 |

14 | 14 | 45 | 100 |

16 | 16 | 45 |

18 | 18 | 45 |

20 | 20 | 45 |

BFL OEM & Customization Services

Flexible Customization Options

BFL offers comprehensive customization to meet diverse machining needs, including:

OEM Branding: Custom logo and packaging printing for your brand.

Dimension Customization: Tailor-made diameter, length, and flute design based on your drawings or samples.

Coating Customization: Optional DLC or Altin coatings to enhance tool performance in specific applications.

Reliable Manufacturing Capability

Backed by a 3,596㎡ factory and SGS certification, we ensure strict quality control from raw material sourcing to finished product inspection. Our 98.3% on-time delivery rate guarantees your production schedule is never delayed.

FAQ

What materials can the BFL 4 flute flat extended end mill process?

It is suitable for machining various metals, especially high-hardness materials like stainless steel, alloy steel, and tool steel with HRC45-65 hardness.

What is the minimum order quantity (MOQ) for this product?

The MOQ is 10 pieces for standard sizes. For custom orders, please contact our sales team for negotiable terms.

How long is the delivery time?

Delivery time varies by order quantity: 5 days for 1-10 pieces, 10 days for 11-100 pieces, and negotiable for bulk orders over 100 pieces.

Does BFL provide after-sales support?

Yes. We offer technical consultation for tool selection and usage guidance. If you encounter quality issues, our team will respond within 3 hours to provide solutions.

English

English