Product Overview

Crafted by Changzhou North Carbide Tool Co., Ltd.—a 17-year verified manufacturer with 99.5% positive reviews—this tungsten carbide milling cutter combines high rigidity, wear resistance, and precision to meet the demands of CNC machining centers, handheld routers, and engraving machines. Suitable for processing hardwood, acrylic, MDF, carbon steel, mold steel, stainless steel, and titanium alloy, it features a taper flute design and PVD heat-resistant coatings, making it ideal for high-speed cutting and reducing tool change frequency. With HRC ratings ranging from 45 to 65, this high precision end mill delivers exceptional surface finish and long service life, catering to both general and specialized machining needs.

Key Features & Benefits

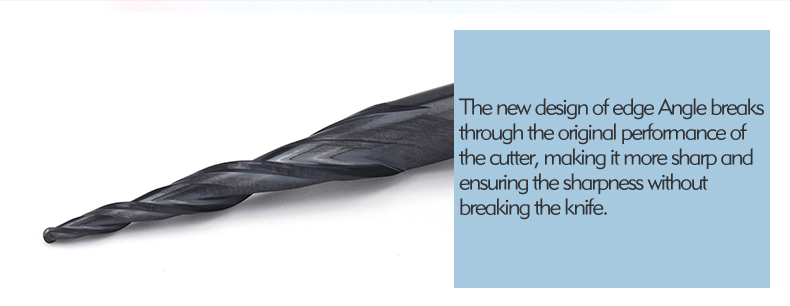

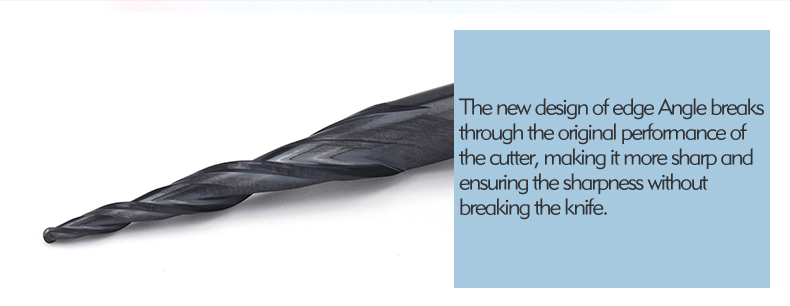

Taper Flute Construction for Enhanced Stability

The unique taper flute design minimizes vibration during cutting, ensuring stable performance even when machining complex shapes. This structural advantage reduces tool deflection, improving machining accuracy and preventing workpiece damage—critical for high-precision projects.

Premium Solid Carbide & Tungsten Carbide Material

Made from 100% high-quality solid carbide (tungsten carbide), the endmill boasts exceptional hardness and wear resistance. It withstands high cutting temperatures and tough materials like inconel and pre-hardened mold steel, extending tool life and lowering production costs.

PVD Heat-Resistant Coatings (TiAlN/AlTiN/TiSiN)

Equipped with PVD-coated layers (TiAlN, AlTiN, TiSiN, or Nano), the cutter offers superior heat resistance and lubricity. The coatings reduce friction, prevent chip adhesion, and enhance wear resistance—perfect for high-speed cutting applications and prolonging tool durability.

High Precision Tolerance (h6)

With a strict h6 tolerance rating, this CNC router bit ensures consistent dimensional accuracy across all workpieces. Whether machining intricate details or large components, it delivers smooth, uniform results that meet professional standards.

2 Flutes for Efficient Chip Removal

The 2-flute configuration optimizes chip flow, preventing clogging and ensuring clean cuts. This design is especially effective for cutting soft and hard materials alike, maintaining cutting efficiency and surface quality.

Product Specifications

Parameter | Details |

Product Name | BFL Solid Carbide Taper Ball Nose Endmill |

Material | Solid Carbide, Tungsten Carbide |

Coating | TiAlN, AlTiN, TiSiN, Nano |

HRC Rating | 45/55/60/65 Degree |

Flute Quantity | 2 Flutes |

Helix Angle | 35 Degree |

Tolerance | h6 |

Applicable Materials | Copper, Steel, Stainless Steel, Carbon Steel, Alloy Steel, Die Steel, Cast Iron, Hardwood, Acrylic, MDF |

Shank Diameter | 4-8mm |

Overall Length | 50-75mm |

Applicable Machines | CNC Machining Center, Handheld Router, Engraving Machine |

BFL OEM & Customization Services

BFL offers comprehensive customization to meet unique project needs, backed by 18 years of experience in carbide cutting tools:

Free Laser Marking: Customize the cutter body with LOGO, specifications, or parameters.

Tailored Label Content: Design labels with brand information or product details.

Custom Outer Packing: Choose personalized packing boxes for branding or protection.

Coating Options: Select from TiAlN, AlTiN, TiSiN, or Nano coatings based on application.

Packaging Tubes: Optional plastic tubes for individual tool storage and protection.

FAQ

What machines are compatible with this taper ball nose endmill?

It works seamlessly with CNC machining centers, handheld routers, and engraving machines—ideal for both industrial and small-scale workshops.

What is the minimum order quantity (MOQ)?

The MOQ is 10 pieces, with flexible lead times (29 days for 1-100 pieces; negotiable for bulk orders).

Can it process high-hardness materials?

Yes! It handles materials up to 65HRC, including stainless steel, titanium alloy, and pre-hardened mold steel.

What payment methods are accepted?

We accept Alipay, Paypal, Western Union, Trade Assurance, UnionPay, and MoneyGram—with a 30% deposit and balance due before shipping.

Does the product come with a warranty?

While there is no formal warranty, our 99.5% positive review rate reflects consistent quality and reliability. Contact our team for after-sales support.

English

English