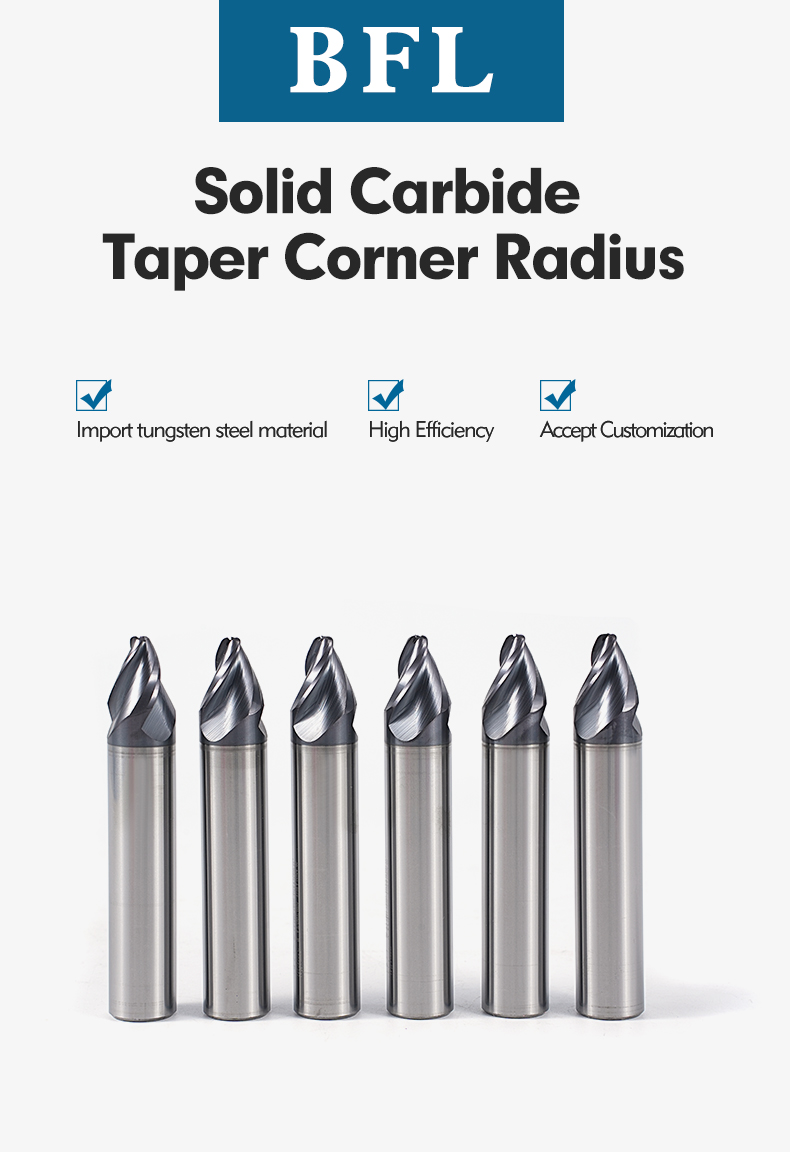

Product Overview

This end mill is engineered exclusively for CNC Machining Centers, delivering exceptional results in metal processing scenarios. Crafted from 100% new Carbide Material (imported tungsten steel), it combines high hardness, wear resistance, and precision to meet the strict demands of industrial metal milling, making it an ideal choice for machining components requiring tight tolerances and smooth surface finishes.

Key Features & Benefits

Premium Carbide Material for Long-Lasting Performance

Made of 100% new Carbide Material (imported tungsten steel), this end mill resists deformation and wear even when cutting high-hardness metals. It supports HRC ratings from 45 to 65, ensuring stable performance across a wide range of metal materials (e.g., carbon steel, alloy steel, stainless steel).

High Precision Taper Corner Radius Design

The Taper Corner Radius structure features a tolerance of ±5um, guaranteeing consistent precision in every cut. The high-precision cutting edge creates smoother, brighter workpieces, eliminating the need for secondary polishing and reducing production time.

Multi-Coating Options for Versatility

Offering a variety of advanced coatings — including AlTiN Coating, TiAlN Coating, TiSiN, TiN, DLC, and NANO — this end mill enhances heat resistance and wear resistance. Different coatings adapt to diverse metal milling needs, extending tool life by up to 50% compared to uncoated alternatives.

3 Flutes for Efficient Metal Milling

The 3-flute design optimizes chip evacuation and cutting efficiency, enabling high-speed Metal Milling without clogging. This reduces the frequency of tool changes, boosting overall production throughput for manufacturers.

Professional Passivation Treatment

Every BFL 3 Flutes End Mill undergoes professional equipment passivation treatment. This process strengthens the cutting edge’s wear resistance, preventing chipping and prolonging the tool’s service life, even in heavy-duty machining.

Product Specifications

Parameter | Details |

Product Name | BFL Carbide 3 Flutes Taper Corner Radius End Mill for Metal |

Flute Count | 3 (2-6 flutes available for customization) |

Coating Types | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO |

Material | 100% New Carbide (Imported Tungsten Steel) |

HRC Rating | 45/55/60/65 Degrees |

Shank Diameter | 4-20mm (customizable) |

MOQ | 10 Pieces |

Lead Time (1-100pcs) | 7 Days |

Shipping Methods | UPS, Fedex, DHL, TNT, EMS, Sea Freight |

Applicable Machine | CNC Machining Center |

Single Package Size | 12×10×8 cm |

Single Gross Weight | 0.500 kg |

BFL OEM & Customization Services

BFL prioritizes flexibility to meet unique customer needs, offering comprehensive OEM & Customization Services tailored to industrial requirements:

Free Custom Laser Marking: Add your brand LOGO, product specifications, or parameters to the end mill body at no extra cost.

Customized Label & Packaging: Design custom labels or outer packing boxes (e.g., specialized tubes) to align with your brand identity.

OEM Support: OEM is Hot Welcome — BFL collaborates with clients to produce end mills under their own brand names, ensuring consistent quality.

Drawing/Sample-Based Customization: Provide 2D/3D drawings or physical samples, and BFL will manufacture fully customized Taper Corner Radius End Mills to your exact specifications.

FAQ

Is Changzhou North Carbide Tool Co., Ltd. a factory or a trader?

We are a professional Carbide End Mill Manufacturer with 17 years of experience, owning production workshops, quality inspection lines, and coating facilities (verified via factory strength displays).

What is the MOQ for the BFL 3 Flutes Taper Corner Radius End Mill?

The minimum order quantity (MOQ) is 10 pieces. For bulk orders (>100 pieces), lead time and pricing can be negotiated for better terms.

Can I choose a specific coating for my order?

Yes. BFL offers multiple coating options (e.g., AlTiN Coating, DLC Coating) to match your machining needs (e.g., high-temperature resistance for stainless steel milling).

How is the product quality guaranteed?

Every BFL Carbide End Mill undergoes strict quality inspection (including precision testing and wear resistance checks) and holds certifications like (EU) 2015/863. Our overall customer rating is 4.9/5, with 94% satisfied reviews.

English

English