Product Overview

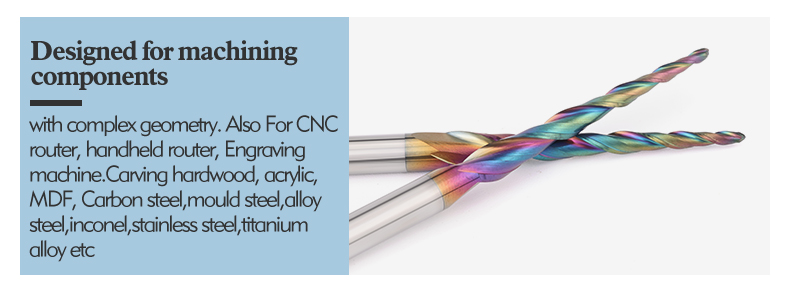

Produced by Changzhou North Carbide Tool Co., Ltd. (a 17-year verified manufacturer with 99.5% positive feedback), this end mill excels in CNC Routers, handheld routers, and engraving machines. Its unique taper ball nose design and high-precision craftsmanship make it suitable for hardwood, MDF, acrylic, carbon steel, mould steel, and even titanium alloy — delivering smooth cuts and consistent performance for industrial and craft applications alike.

Key Features & Benefits

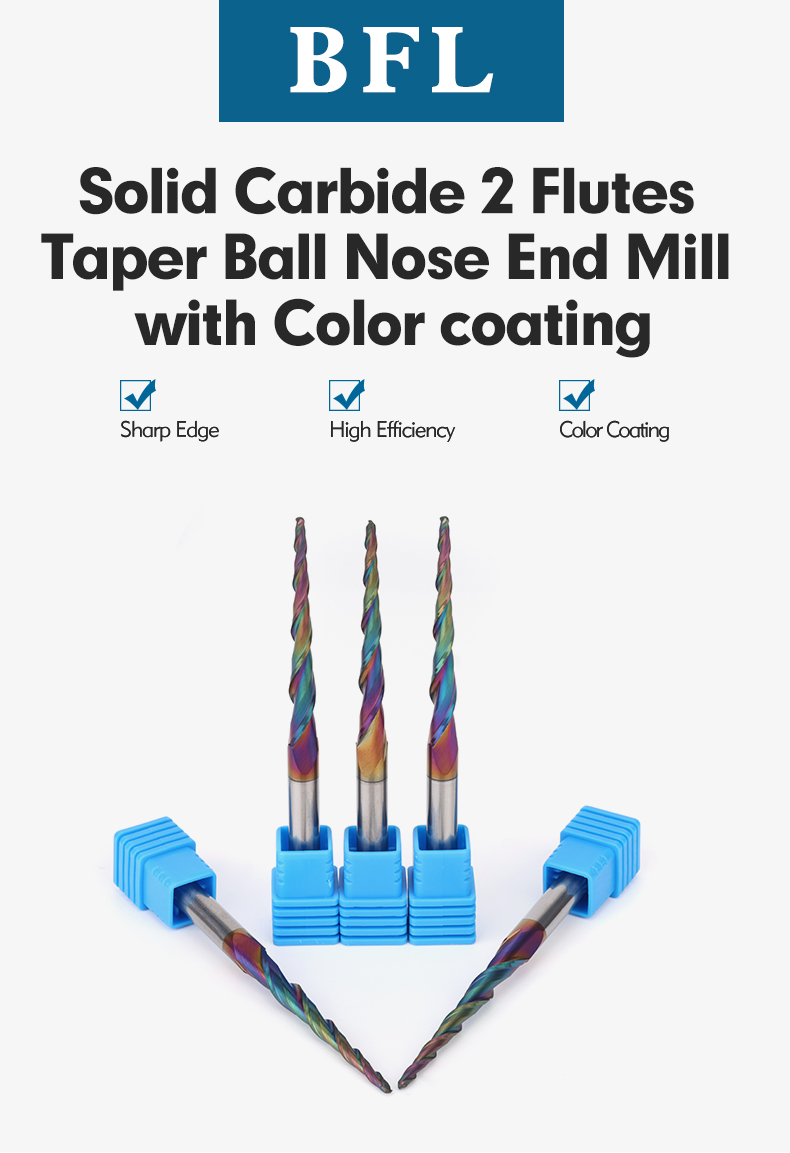

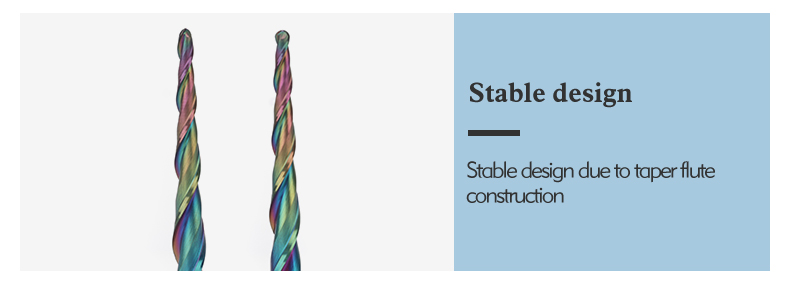

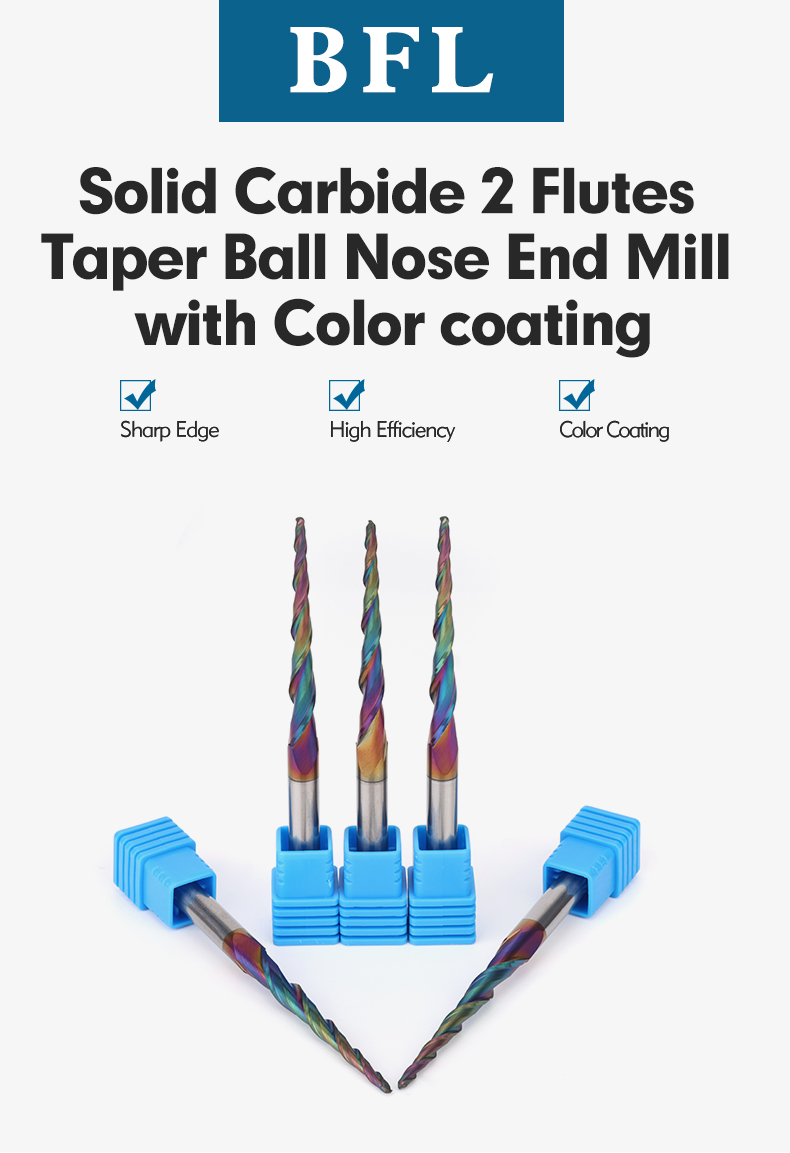

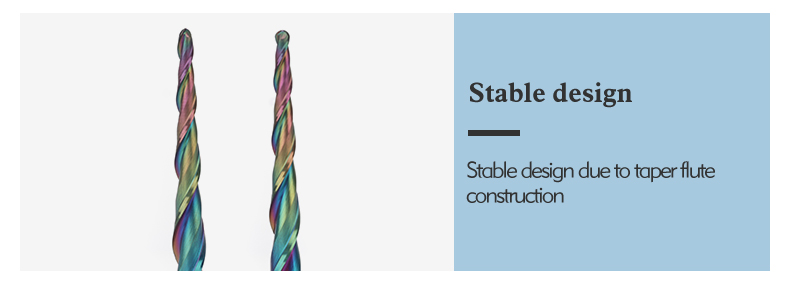

Precision 2 Flutes Taper Ball Nose Design

The 2 Flutes Taper Ball Nose structure is optimized for machining components with complex geometries (e.g., curved surfaces, 3D contours). It prevents chattering during cutting, ensuring a smoother surface finish and eliminating post-processing work.

High-Quality Carbide for Durability

Crafted from 100% new Carbide Material (tungsten alloy), this end mill withstands high cutting forces and supports HRC 45-65 ratings. It maintains sharpness longer than standard tools, reducing tool replacement frequency and saving production costs.

Heat-Resistant PVD Coatings

Equipped with PVD-Applied Coatings (AlTiN, TiAlN, TiSiN, TiN, DLC, NANO), the end mill resists high temperatures and wear. This makes it ideal for high-speed cutting of tough materials like stainless steel and inconel.

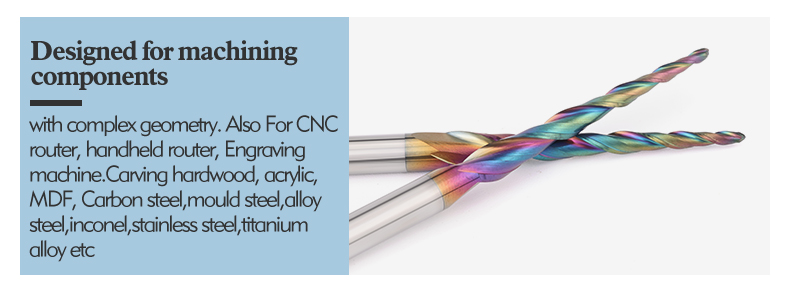

Versatility for Wood & Metal Machining

Unlike single-material end mills, this tool processes both wood (hardwood, MDF, particle board) and metal (carbon steel, alloy steel, titanium alloy). Its multi-material compatibility reduces tool inventory for workshops.

Product Specifications

Parameter | Details |

Product Name | BFL Carbide Precision 2 Flutes Taper Ball Nose End Mill Tools |

Flute Count | 2 (2-6 flutes available for customization) |

Coating Types | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO (PVD-applied) |

Material | 100% New Carbide (Tungsten Alloy) |

HRC Rating | 45/55/60/65 Degrees |

Shank Diameter | 0.2-20mm (customizable) |

MOQ | 10 Pieces |

Sample Policy | Free Samples Available |

Monthly Supply Capacity | 300,000 Pieces |

Applicable Materials | Wood (hardwood, MDF), Metal (carbon steel, stainless steel, titanium) |

Packaging Details | 1pc/plastic pipe, 10pcs/group; air bubble paper + custom boxes optional |

Port of Dispatch | Shanghai, Qingdao, Guangdong, Beijing, Ningbo, Shenzhen |

BFL OEM & Customization Services

BFL’s Customization Services cater to diverse industry needs, ensuring tools align with your unique machining requirements:

Custom LOGO Printing: Add your brand logo to the end mill body (minimum order: 100 pieces) for brand recognition.

Tailored Packaging: Choose from standard plastic pipes or customize outer boxes (e.g., branded cartons) to protect tools during shipping and storage.

Full Customization: Provide drawings or samples for specialized designs (e.g., unique taper angles, ball nose radii) — BFL has focused on custom Carbide Tools since 2013.

ODM Support: Collaborate with BFL’s R&D team to develop original taper ball nose end mills for niche applications (e.g., aerospace component machining).

FAQ

Does BFL provide free samples for the 2 Flutes Taper Ball Nose End Mill?

Yes. We offer Free Samples to help you test the tool’s performance (e.g., cutting smoothness, wear resistance) with your target materials (wood or metal).

Can BFL ship products to my forwarder in China?

Absolutely. If you have a forwarder in China, we will directly ship the CNC Router Bits to their warehouse, simplifying your supply chain.

What is the monthly supply capacity for this end mill?

Our monthly production capacity is 300,000 pieces, ensuring we can meet large-volume orders for industrial clients without delays.

Can BFL produce special carbide tools beyond standard designs?

Yes. Since 2013, we have shifted our focus to custom tools. Provide your drawings or samples, and we will manufacture specialized taper ball nose end mills (e.g., unique shank diameters, coating types) to your specifications.

English

English