Product Overview

As a leading ODM Solid Carbide Router Bit supplier with 17 years of experience, BFL delivers this tool with a focus on large chip capacity, precision, and customization. Featuring a Large Chip Space End Mill design and optional Gold Coated Carbide Cutter finish, it excels in processing particle board, melamine, copper, cast iron, and carbon steel. With 99.5% positive feedback and global exhibition presence (Moscow Tool Fair, EMO Germany), this tool is a top choice for manufacturers seeking reliability and flexibility.

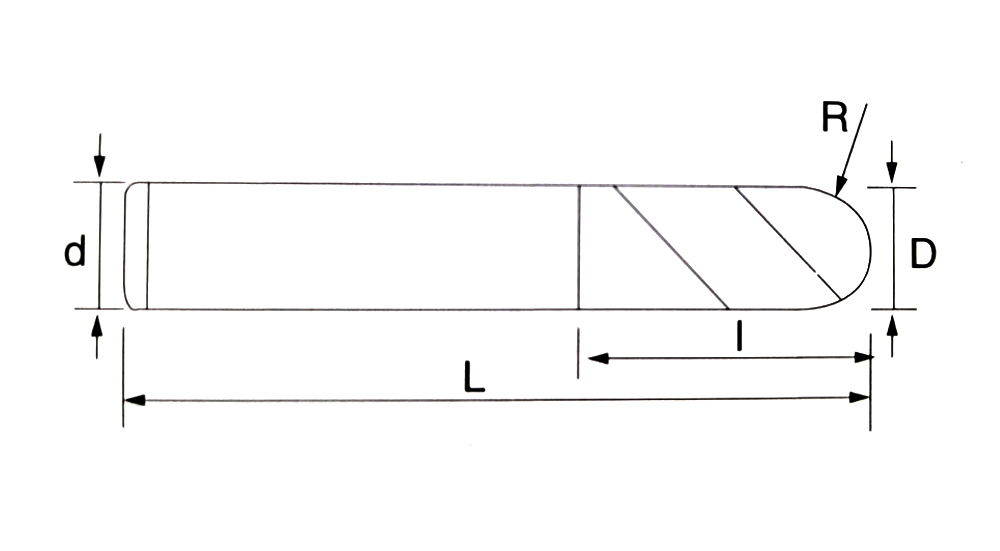

Product Specifications

Parameter | Details |

Material | Micro Grain Tungsten Steel Carbide (100% new material) |

Flute Count | 2 flutes (customizable to 2-6 flutes) |

HRC Range | 45/55/60/65 Degrees (in-stock options available) |

Shank Diameter | Shank Diameter Range 4-20mm |

Overall Length | 50mm, 60mm, 75mm, 100mm (per model specifications) |

Outside Diameter | R0.5 to R10 (see cutting parameters for details) |

Applicable Machines | CNC Router, Woodworking CNC Router, Advertising CNC Router, Machining Center |

Suitable Materials | Particle board, melamine, copper, cast iron, carbon steel, etc. |

Packaging | Single package: Single Package Size 5X10X10 cm; Gross weight: 0.5kg |

MOQ | 10 Pieces |

Shipment | UPS/Fedex/DHL/TNT/EMS/Sea |

Lead Time | 10 days for 1-10 pieces; Negotiable for orders over 10 pieces |

Project code | Outer diameter | | | |

BFL-ER-010 | R0.5 | 4 | 2 | 50 |

BFL-ER-020 | R1 | 4 | 4 | 50 |

BFL-ER-030 | R1.5 | 3 | 6 | 50 |

BFL-ER-040 | R2 | 4 | 8 | 50 |

BFL-ER-610 | R0.5 | 6 | 2 | 50 |

BFL-ER-620 | R1 | 6 | 4 | 50 |

BFL-ER-630 | R1.5 | 6 | 6 | 50 |

BFL-ER-640 | R2 | 6 | 8 | 50 |

BFL-ER-650 | R2.5 | 5 | 10 | 50 |

BFL-ER-660 | R3 | 6 | 12 | 50 |

BFL-ER-080 | R4 | 8 | 16 | 60 |

BFL-ER-100 | R5 | 10 | 20 | 75 |

BFL-ER-200 | R10 | 20 | 30 | 100 |

Key Features & Benefits

Large Chip Space for Smooth Machining

The Large Chip Space design is a standout feature, enabling rapid Chip Evacuation during high-speed cutting. This prevents chip accumulation and heat buildup, ensuring consistent cutting performance and reducing tool wear. Ideal for materials prone to chip clogging (e.g., particle board, melamine), the design boosts Production Efficiency by minimizing downtime for cleaning.

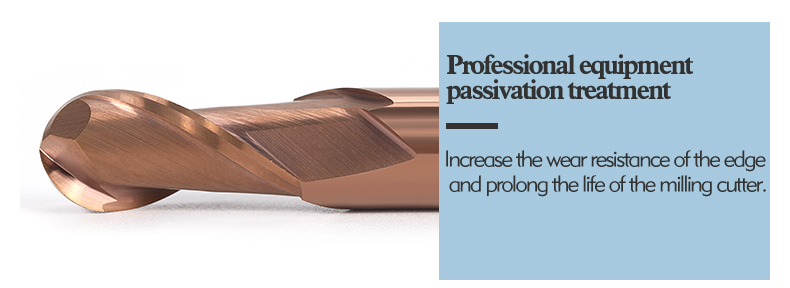

High-Precision Passivated Cutting Edge

Each end mill undergoes professional equipment passivation treatment, strengthening the Passivated Cutting Edge to resist wear and chipping. The High Precision Cutting Edge (achieved via advanced grinding technology) delivers superior Workpiece Brightness—no post-machining polishing required for many applications. This precision makes the tool perfect for decorative components and high-end parts.

Versatile Coatings Including Gold Coating

BFL offers a range of coatings, including AlTiN, DLC, NANO, and the popular Gold Coating. The gold coating not only enhances aesthetics but also provides exceptional heat resistance and lubricity, extending tool life in demanding environments. All Versatile Coatings are engineered to improve adhesion and durability, adapting to HRC45-65 materials with ease.

2-6 Flutes Customizable Design

While the standard model features 2 flutes, BFL supports 2-6 Flutes Customization to match specific machining needs. The 2-flute variant prioritizes chip evacuation and speed, while higher flute counts (up to 6) enhance surface finish for precision tasks. Crafted from Solid Carbide Strength material, the tool maintains rigidity across all flute configurations, ensuring stability in diverse applications.

BFL OEM & Customization Services

BFL stands out for its flexible ODM Carbide Tool and OEM solutions, including:

Full customization support (OEM, ODM, OBM Support) to align with brand needs.

Free laser marking (LOGO, parameters, or specifications) on the tool body.

Customizable labels, outer packaging, and optional packaging tubes.

Special tool development based on customer drawings or samples—our core focus since 2013.

With in-house production (from coarse grinding to packaging) and strict quality control, BFL ensures customized tools meet the same high standards as standard products.

FAQ

Does the 2 Flutes Ball Nose End Mill come with a Gold Coating option?

Yes! We offer Gold Coated Carbide Cutter as one of the coating options, along with AlTiN, DLC, and NANO coatings. The gold coating enhances lubricity and heat resistance for demanding applications.

What is the MOQ for custom ODM Solid Carbide Router Bit orders?

The minimum order quantity is 10 pieces, even for customized designs. For bulk custom orders, we offer flexible terms and competitive pricing.

How long is the lead time for small orders of Large Chip Space End Mill?

For orders of 1-10 pieces, the lead time is 10 days. For orders over 10 pieces, lead time is negotiable—we prioritize fast delivery without compromising quality.

Is this Solid Carbide Router Bit suitable for woodworking projects?

Absolutely! It’s specifically designed for Woodworking CNC Router and excels in processing particle board, melamine, and other wood-based materials. Customers from Canada and Brazil have praised its performance on wood products.

Can you provide OBM support for the Carbide Cutting Tool?

Yes, we offer OBM support in addition to OEM and ODM services. Our team can help with branding, packaging design, and product certification to meet your market requirements.

English

English