Product Overview

This High Precision Milling Tool delivers exceptional performance on copper, cast iron, carbon steel, and alloy steel. Backed by a 99.5% positive review rate and EU (2015/863) certification, the Carbide Cutting Tool combines durability, efficiency, and versatility to meet the demands of professional machining projects worldwide. Whether for slot processing, profile cutting, or hole drilling, this end mill is designed to elevate surface finish and reduce production time.

Key Features & Benefits

Sharp & Wear-Resistant Cutting Edge

Crafted with High Precision Grinding and polishing, the Sharp Cutting Edge of this 4-flute end mill ensures smooth, low-resistance cutting. The cutting edge over the center minimizes machining force, while the high-strength carbide material (100% new micro grain tungsten steel) enhances durability. This design not only improves Surface Finish of workpieces but also extends tool life, reducing replacement costs for manufacturers.

4-Flute Chatter-Resistant Design

The innovative 4-Flute Design features a chatter-resistant structure that boosts tool rigidity, even during high-speed machining. This stability prevents vibration-induced defects, making the tool ideal for precision contouring and deep slotting. Additionally, the double-edge design further enhances rigidity, ensuring consistent performance across long production runs—perfect for industrial-scale applications requiring reliability.

Multiple High-Performance Coatings

Available in AlTiN, TiCN, TiSiN, and other High-Performance Coatings, the end mill adapts to diverse machining needs. These coatings significantly improve Wear Resistance and heat resistance, allowing the tool to handle materials with hardness ranging from HRC45 to HRC65. The HRC 65 Carbide Tool variant stands out for machining hardened steels, delivering consistent results without compromising efficiency.

Efficient Chip Removal System

Equipped with a large-capacity Junk Slot, the end mill facilitates rapid Chip Removal Efficiency. This design prevents chip clogging, reduces heat buildup, and maintains cutting precision—critical for continuous machining operations. The flute geometry also supports vertical feed processing, expanding the tool’s versatility for complex machining tasks.

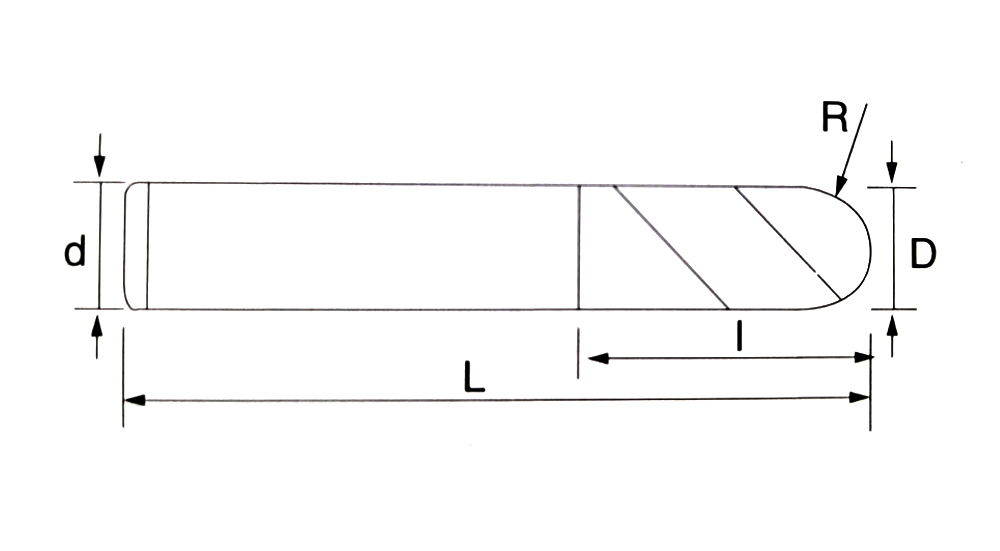

Product Specifications

Parameter | Details |

Material | Micro Grain Tungsten Steel (100% new solid carbide) |

Flute Count | 4 flutes |

HRC Range | 45/55/60/65 Degrees |

Shank Diameter | Shank Diameter 4-20mm |

Overall Length | 50mm, 60mm, 75mm, 100mm (varies by model) |

Outside Diameter | R0.5 to R10 (see model chart for details) |

Applicable Machines | CNC Machining Center, CNC Router, Woodworking Machine |

Suitable Materials | Copper, cast iron, carbon steel, alloy steel, etc. |

Packaging | Single package: 5X5X6 cm; Gross weight: 0.5kg |

MOQ | MOQ 10 Pieces |

Shipment | UPS/Fedex/DHL/TNT/EMS/Sea |

Lead Time | 5 days for 1-100 pieces; Negotiable for bulk orders |

Project code | Outer diameter | Handle diameter | Flute length | Total length |

BFL-ER-010 | R0.5 | 4 | 2 | 50 |

BFL-ER-020 | R1 | 4 | 4 | 50 |

BFL-ER-030 | R1.5 | 3 | 6 | 50 |

BFL-ER-040 | R2 | 4 | 8 | 50 |

BFL-ER-610 | R0.5 | 6 | 2 | 50 |

BFL-ER-620 | R1 | 6 | 4 | 50 |

BFL-ER-630 | R1.5 | 6 | 6 | 50 |

BFL-ER-640 | R2 | 6 | 8 | 50 |

BFL-ER-650 | R2.5 | 5 | 10 | 50 |

BFL-ER-660 | R3 | 6 | 12 | 50 |

BFL-ER-080 | R4 | 8 | 16 | 60 |

BFL-ER-100 | R5 | 10 | 20 | 75 |

BFL-ER-200 | R10 | 20 | 30 | 100 |

BFL OEM & Customization Services

BFL offers comprehensive OEM Carbide Tool solutions to meet unique customer needs. Key customization options include:

Free Custom Laser Marking (LOGO, specifications, or parameters) on the tool body.

Customizable label content and outer packing boxes.

Drawing-Based Customization and sample-based customization for special carbide tools (available since 2013).

Support for small-batch customization without compromising quality or lead time.

As a factory-direct supplier, BFL ensures full control over production—from coarse grinding to coating and packaging—guaranteeing consistent quality for every customized order.

FAQ

Are you a professional manufacturer of the 4 Flutes Ball Nose End Mill?

Yes! We are a verified manufacturer with 17+ years of experience in producing Solid Carbide End Mill and other carbide cutting tools. Our factory is equipped with TTB/ANCA/DECKEL machines for precision production.

Do you offer free shipping for Solid Carbide End Mill orders?

We don’t provide free shipping, but bulk orders qualify for shipping discounts. We partner with top logistics providers (UPS, Fedex, etc.) to offer competitive rates for global delivery.

Can you customize special Carbide Cutting Tools according to my samples?

Absolutely! We specialize in Drawing-Based Customization and sample-based customization for special carbide tools. Simply share your requirements, and our engineering team will deliver tailored solutions.

Can you ship the CNC Machining Center Cutter to my forwarder in China?

Yes, we happily ship products to customer-designated forwarders in China. Please provide your forwarder’s contact details when placing the order for smooth coordination.

What makes your High Precision Milling Tool stand out from competitors?

Our end mill combines 17 years of manufacturing expertise, high-quality micro grain carbide, precision grinding, and multiple performance coatings. With a 4.9/5 customer rating and 99.5% positive reviews, it’s trusted by clients in Azerbaijan, Thailand, Poland, and beyond.

English

English