Product Overview

Crafted from premium micro-grain tungsten carbide, this end mill delivers exceptional toughness and wear resistance, making it suitable for both high-speed cutting and heavy-duty machining tasks. It supports multiple HRC ratings (45 HRC, 55 HRC, 58 HRC, 60 HRC, 65 HRC) to match diverse material hardness needs and offers various coating options—such as ALTIN, TiAlN, TiSiN, TiN, DLC, and nano-coatings—to enhance heat resistance and extend tool life. With in-stock availability and fast delivery, it is a reliable solution for manufacturing plants, machining workshops, and CNC processing centers.

Key Features & Benefits

High Heat-Resistant Coatings

The optional ALTIN coating enables high-speed processing by minimizing heat accumulation during cutting, protecting the tool from thermal damage and prolonging its service life. Other coatings like TiAlN and DLC further boost wear resistance for different machining scenarios.

Premium Micro-Grain Carbide Material

Made from 100% virgin micro-grain carbide powder, the end mill exhibits superior toughness and impact resistance, reducing the risk of chipping even when machining ultra-hard materials (e.g., 65 HRC mould steel).

Vibration Reduction Design

To avoid machining vibration (a major cause of poor surface finish), we recommend selecting the minimum required overhang. This design also allows flexible adjustment of rpm and feed rate based on cutting depth and machine rigidity, ensuring stable operation.

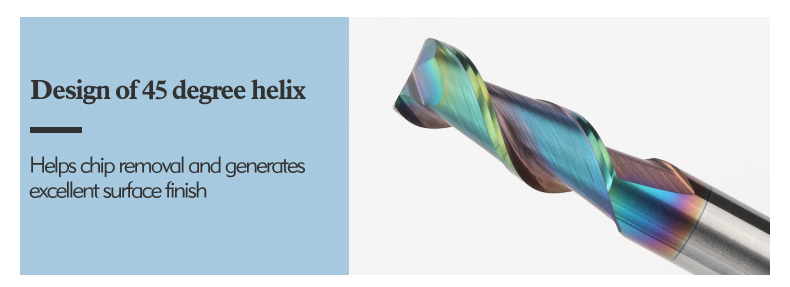

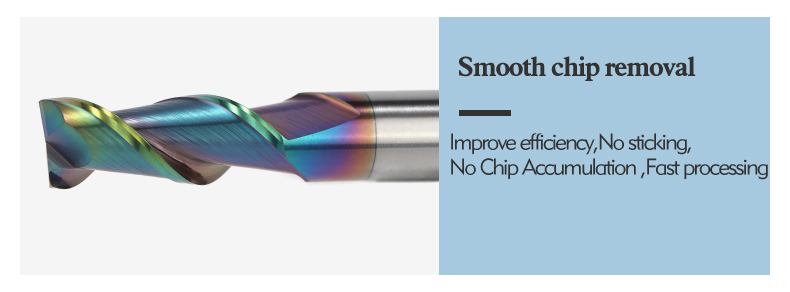

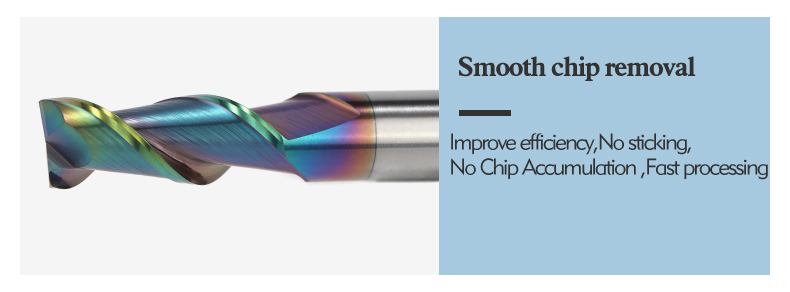

Enhanced Surface Smoothness

Its precision-ground flute geometry lowers the friction coefficient during cutting, improving workpiece surface finish and reducing the need for post-processing—saving valuable production time.

ISO 9001 Quality Assurance

Each end mill undergoes 200% inspection under the ISO 9001:2008 quality system, covering dimensional accuracy, coating adhesion, and hardness, ensuring consistent performance across every unit.

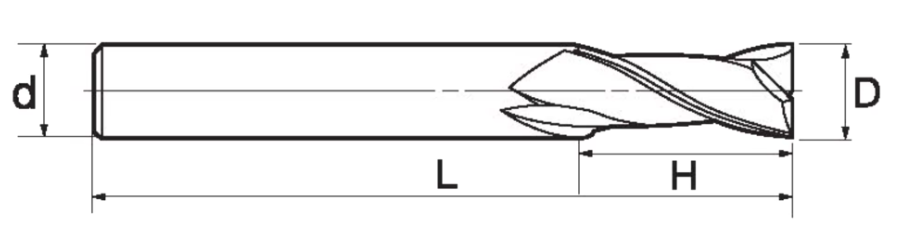

Product Specifications

Product Code | Flute Diameter (mm) | Flute Length (mm) | Overall Length (mm) | Shank Diameter (mm) | HRC Rating | Coating Option |

BFL-AD-010 | 1.0 | 3 | 50 | 4 | 45-65 HRC | ALTIN/TiAlN |

BFL-AD-020 | 2.0 | 6 | 50 | 4 | 45-65 HRC | TiSiN/DLC |

BFL-AD-030 | 3.0 | 8 | 50 | 3 | 45-65 HRC | TiN/Nano |

BFL-AD-100 | 10.0 | 25 | 75 | 10 | 45-65 HRC | TiAlN/Nano |

BFL-AD-200 | 20.0 | 45 | 100 | 20 | 45-65 HRC | ALTIN/DLC |

BFL OEM & Customization Services

Basic Customization

Customized Logo & Packaging: Print your brand logo on the tool or design tailored packaging (e.g., plastic tube packs, bubble-wrap boxes) to align with your brand identity.

Dimension Adjustments: Modify flute diameter, length, or shank size based on your drawings or samples.

Advanced Customization

Coating Tailoring: Select specific coatings (e.g., DLC for low friction) or adjust coating thickness for specialized applications.

Specialized Geometry: Design custom flute shapes for unique materials (e.g., titanium alloys) or machining processes (e.g., deep-hole cutting).

FAQ

What is the minimum order quantity (MOQ) for this end mill?

The standard MOQ is 10 pieces per product code. Bulk orders (over 1000 pieces) qualify for preferential pricing.

How long is the delivery time?

In-stock models ship within 3-10 days; customized orders take 7-14 days depending on complexity.

Can I get a sample before placing a large order?

Yes, we provide sample testing. Contact our team to discuss sample availability and shipping costs.

How to resolve vibration during long-overhang machining?

Reduce rpm and feed rate, optimize machine rigidity, or switch to a shorter-overhang model to improve stability.

English

English