Product Overview

Designed exclusively for CNC Machining Centers, this high-performance end mill combines top-grade carbide materials with advanced manufacturing techniques to deliver exceptional results in high-speed cutting applications. Its ultra-smooth polished surface, 3-flute structure, and 45-degree helix angle address core pain points like chip accumulation, surface roughness, and low processing efficiency—making it a top choice for industries ranging from automotive parts production to electronic component manufacturing. With a 99.5% positive review rate and exports to Azerbaijan, Thailand, and Poland, this aluminum-specific end mill stands out for reliability and consistent performance.

Key Features & Benefits

High Polished Cutting Edge & Slot

The mirror ultra-finish surface on the cutting edge and slot eliminates residue buildup during machining, ensuring a flawless workpiece surface. This high-polish design reduces friction between the tool and material, minimizing wear and extending tool life while maintaining high precision across hundreds of cuts.

3 Flutes Design for Maximum Chip Removal

Equipped with 3 flutes, this end mill features a large-capacity slot that enables efficient chip evacuation. Unlike fewer-flute tools, the 3-flute structure prevents chip clogging, reduces cutting force, and enhances processing stability—critical for high-speed cutting of soft metals like aluminum.

45-Degree Helix Angle

The optimized 45-degree helix angle promotes smooth chip flow, reduces vibration, and generates an excellent surface finish. It also improves cutting efficiency by distributing load evenly across the flute edges, making the tool ideal for both slotting and contouring operations.

Premium Tungsten Carbide Material

Crafted from high-quality tungsten carbide (available in YG10X, YG10.2, K44, and H10F grades), the end mill boasts exceptional flexural strength (up to 4300N/mm²). This solid carbide construction ensures resistance to chipping and deformation, even under intense cutting conditions.

High Precision with h6 Tolerance

With an h6 tolerance rating, this end mill delivers tight dimensional accuracy, meeting the strict requirements of precision machining projects. Whether you’re producing small electronic parts or large automotive components, the tool’s consistency guarantees uniform results.

Uncoated Coating for Aluminum Compatibility

The uncoated design is specifically tailored for aluminum and non-ferrous metals, avoiding material adhesion and ensuring clean cuts. Unlike coated tools that may react with soft metals, this uncoated end mill maintains sharpness and performance throughout its lifespan.

Large Capacity Slot for Efficient Processing

The tool’s large-capacity slot enhances chip removal speed, reducing downtime for cleaning and increasing overall productivity. This feature is especially valuable for high-volume production environments where efficiency is key.

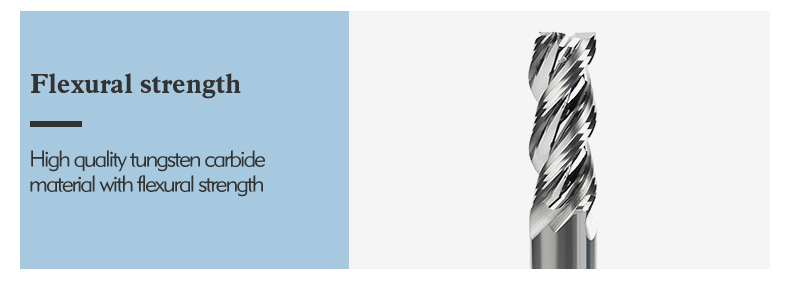

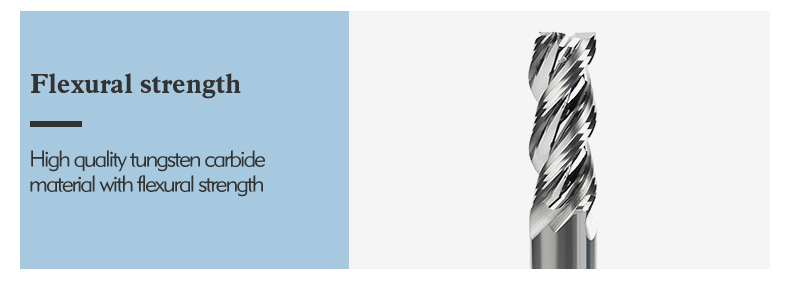

Exceptional Flexural Strength

The premium carbide material and rigorous manufacturing process result in outstanding flexural strength, allowing the end mill to withstand high cutting forces without breaking or bending. This durability translates to lower tool replacement costs and higher operational efficiency.

Product Specifications

Parameter | Details |

Product Name | BFL High Polished Solid Carbide 5mm Aluminum End Mill |

Diameter | 5mm |

Overall Length | 50mm |

Flutes | 3 Flutes |

Material | Tungsten Carbide (YG10X/YG10.2/K44/H10F) |

Hardness (HRC) | 45/55/60/65 (standard 58HRC) |

Helix Angle | 45° |

Tolerance | h6 |

Coating | Uncoated |

Applicable Materials | Aluminum, aluminum alloy, copper alloy |

Controlling Mode | CNC |

Usage | High Speed Cutting |

MOQ | 1 Piece |

Delivery Time | 2-3 Days (1-10 pieces: 10 days) |

BFL OEM & Customization Services

Laser Marking Customization

Take advantage of free customized body laser marking, including your LOGO, specifications, or parameters. This service enhances brand visibility and simplifies tool identification in busy workshops.

Label & Packaging Customization

Customize label content and outer packing boxes to align with your brand standards. Optional packaging tubes are also available for added protection during transportation.

Design & Parameter Customization

BFL supports full customization, including OEM, ODM, and OBM services. Whether you need adjusted diameters, helix angles, or material grades, our team works with you to create tools tailored to your specific machining needs.

FAQ

What is the minimum order quantity (MOQ) for this end mill?

The MOQ is 1 piece for standard orders, making it easy to test the tool before placing bulk purchases. For quantities over 10 pieces, lead time is negotiable.

Can this end mill be used for materials other than aluminum?

This tool is specifically designed for aluminum, aluminum alloys, and copper alloys. For other materials (e.g., steel, plastic), check BFL’s multi-material end mill range.

What transportation options are available?

We offer sea, express (DHL/FedEx/UPS), and air shipping to meet your delivery timeline.

Is technical support provided for customization?

Yes! Our R&D team provides full support for drawing-based and sample-based customization, ensuring the final product meets your exact requirements.

How does the high-polish surface benefit my operations?

The mirror finish reduces friction, prevents chip adhesion, and delivers a smoother workpiece surface—reducing post-processing time and improving product quality.

English

English