Product Overview

As a product of Changzhou North Carbide Tool Co., Ltd. — a 17-year verified manufacturer and trader — this high polished end mill features a 45° helix angle, large capacity slot, and extreme sharpness, delivering exceptional chip removal and surface finish. With an HRC60 rating, uncoated carbide construction, and 2-6 flute options, it outperforms conventional tools in CNC machining centers. Trusted by customers in Azerbaijan, Thailand, and Poland (with a 99.5% positive review rate), this aluminum CNC milling cutter is the top choice for precision metalworking in automotive, electronics, and aerospace industries.

Key Features & Benefits

High Polished Cutting Edge & Slot

Mirror Ultra-Finish Surface

The cutting edge and slot feature a mirror ultra-finish (Ra ≤ 0.2um), ensuring no material residue adheres during processing. This design guarantees a smooth, burr-free surface on aluminum workpieces, eliminating the need for post-processing.

Aluminum-Friendly Polishing

The high polished finish is tailored for aluminum and its alloys, preventing aluminum chips from sticking to the tool. This reduces downtime for cleaning and maintains consistent cutting performance.

Premium Carbide Material for Aluminum Processing

High Hardness & Wear Resistance

Crafted from 100% new carbide material, the tool offers superior hardness (HRC60) and wear resistance. It withstands the demands of high-speed aluminum milling, ensuring long-term reliability and consistent precision.

Stability & Dimensional Accuracy

Carbide’s excellent dimensional stability minimizes tool deflection during cutting, resulting in precise, consistent workpiece dimensions. This is critical for high-tolerance aluminum components.

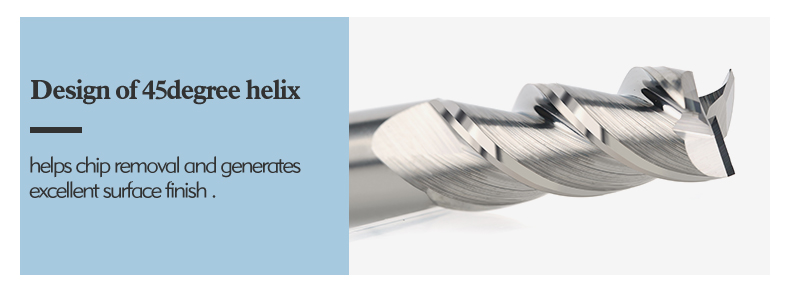

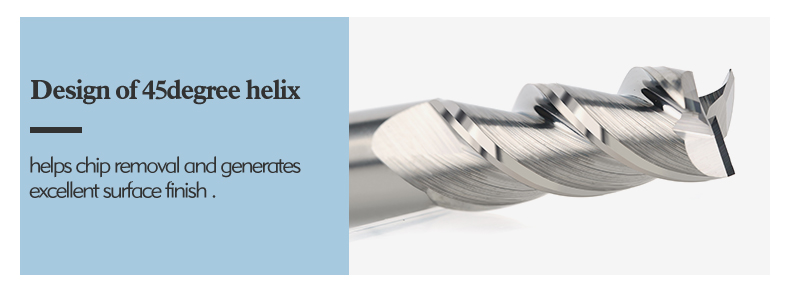

45° Helix Angle for Efficient Chip Removal

Optimized Chip Flow

The 45° helix angle end mill is engineered to optimize chip evacuation. The spiral design guides chips away from the cutting zone quickly, preventing clogging and reducing heat buildup — a common challenge in aluminum milling.

Reduced Vibration & Improved Finish

The 45° angle reduces cutting vibration, which enhances surface finish and extends tool life. This makes the tool ideal for both roughing and finishing operations on aluminum workpieces.

Extreme Sharpness & Reduced Cutting Force

Precision-Ground Cutting Edge

The cutting edge undergoes precision grinding to achieve extreme sharpness. This reduces cutting force to 30%-50% of conventional tools, preventing aluminum tearing and burr formation — a major issue in soft metal processing.

Energy Efficiency & Tool Longevity

Lower cutting force not only improves workpiece quality but also reduces machine load and tool wear. This translates to energy savings and a longer tool service life, lowering overall production costs.

Large Capacity Slot Design

High Chipping Removal Efficiency

The large capacity slot of the end mill provides ample space for chips, enabling efficient chip removal even during high-speed, deep-cut milling. This design minimizes tool overheating and ensures continuous operation.

Versatility for Thick & Thin Materials

Whether processing thick aluminum blocks or thin sheets, the large slot design adapts to varying chip volumes, maintaining performance across diverse applications.

Product Specifications

Product Name | Blade Diameter (mm) | Shank Diameter (mm) | Overall Length (mm) | Flute Count | Helix Angle | HRC Rating | Coating | Material | Tolerance | MOQ (Pieces) |

BFL High Performance High Polished End Mill | 4 | 4 | 50 | 3 | 45° | 60 | Uncoated | Carbide | h6 | 10 |

Custom Aluminum Milling Cutter | 4-20 | 4-20 | 38-150 | 2-6 | 45° | 60 | Optional | Carbide | h6 | 10 |

BFL OEM & Customization Services

OEM Branding & Laser Marking

Custom LOGO & Parameter Marking

We offer OEM branding with free laser marking on the tool body, including your brand LOGO, product specifications, or technical parameters. This service helps you build brand recognition in the global market.

High-Visibility Markings

Our laser markings are clear, scratch-resistant, and easy to read — even after prolonged use. They comply with international standards for tool identification.

Customized Specifications for Aluminum Applications

Tailored Diameter & Length

Adjust blade diameter, shank diameter, and overall length to match your specific aluminum processing needs. Whether you require a micro-diameter tool for electronics or a large cutter for automotive parts, we deliver precise customization.

Flute Count & Helix Angle Adjustment

Modify flute count (2-6) or helix angle to optimize performance for your application. For example, more flutes improve surface finish, while a modified helix angle can enhance chip removal for specific aluminum alloys.

Tailored Label & Packaging

Custom Label Content

Customize label content to include product features, usage guidelines, or compliance information. Our labels are designed for clarity and compatibility with global shipping requirements.

Protective Packaging Solutions

Choose from standard packaging or custom outer boxes and packaging tubes to protect the tools during transit. We ensure your tools arrive in perfect condition, regardless of shipping distance.

Special Tool Development from Drawings/Samples

Custom Aluminum Cutting Tools

Since 2013, we have specialized in developing special carbide tools for aluminum processing. We accept drawings or samples to create tools tailored to your unique workflow and workpiece requirements.

Technical Support & Prototyping

Our engineering team provides full technical support, from design refinement to prototyping. We test custom tools to ensure they meet your performance standards before mass production.

English

English