Product Overview

rafted from high-grade tungsten carbide, this tool is engineered to handle hard materials up to 65HRC, featuring advanced nano coating technology and edge passivation treatment to resist wear and extend service life. Its ultra-small diameter range (0.2mm-0.9mm) makes it perfect for micro-machining in automotive molds, plastic processing, and precision engineering, with full OBM/ODM/OEM support to meet unique customer needs.

Key Features & Benefits

Material & Coating Advantages

Nano Coating Technology: Multilayer nano coatings significantly boost surface hardness and wear resistance, enabling stable cutting of HRC65 materials without frequent tool changes.

High-Grade Tungsten Carbide: Ensures exceptional tool strength and durability, even when machining high-hardness substrates, reducing downtime and replacement costs.

Multilayer Film Coating: Adds a heat-resistant barrier, protecting the tool from high temperatures generated during high-speed micro-milling.

Design & Manufacturing Highlights

Edge Passivation Treatment: Smooths tool edges to prevent cracking and chipping, extending service life and reducing machining errors in ultra-precise tasks.

German Walther Equipment Production: Uses imported German Walther CNC machines to achieve ±0.001mm precision, guaranteeing consistent tool performance and reliability.

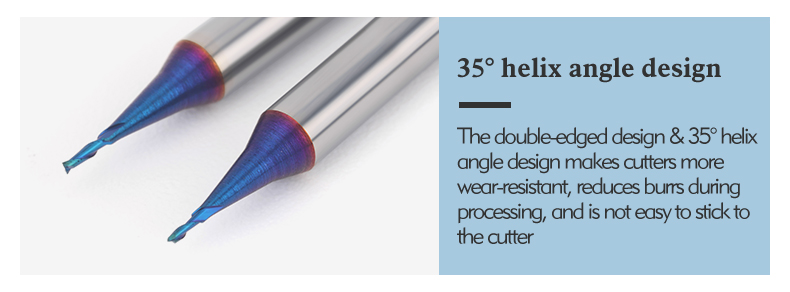

2 Flutes Design: Optimizes chip flow for ultra-small diameters, minimizing material buildup and ensuring clean, burr-free cuts in intricate applications.

0.2mm-0.9mm Micro Diameter Range: Covers ultra-fine machining needs, perfect for producing intricate parts like mold inserts, micro-components, and precision fixtures.

Product Specifications

Parameter | Details |

Product Name | HRC65 Custom ODM & OEM Supported 0.2mm-0.9mm Carbide Square End Mill Milling Cutter |

Material | High-Grade Tungsten Carbide |

Flute Number | 2 Flutes |

HRC Rating | 55HRC, 60HRC, 65HRC |

Diameter Range | 0.1mm-0.9mm (custom diameters available) |

Overall Length | 50mm (standard) |

Helix Angle | 30°, 35°, 45° (optional) |

Coating Type | Nano Coating (Multilayer Film) |

Customization Support | OBM, ODM, OEM |

MOQ | 10 Pieces |

Applicable Fields | Automotive Molds, Plastic Processing, Precision Machining |

HRC65 OEM & Customization Services

Tool Design & Production Customization

ODM Tool Design: Develop non-standard HRC65 square end mills based on customer drawings, samples, or technical requirements, ideal for specialized micro-machining tasks.

OEM Production: Manufacture tools under your brand name, with custom laser marking (LOGOs, specifications, batch numbers) to maintain brand consistency.

Custom Diameter Tuning: Adjust diameters within or beyond the 0.2mm-0.9mm range to fit unique machining setups and project specifications.

Sample & Packaging Solutions

Rapid Sample Provision: Deliver samples within 1-2 days (subject to MOQ) to verify quality, performance, and compatibility before placing bulk orders.

Branded Packaging: Design custom labels and packing boxes to align with your brand identity, enhance product presentation, and ensure safe shipping.

FAQ

Product & Application

What is the smallest diameter available for this HRC65 square end mill?

The standard minimum diameter is 0.2mm, but we offer custom diameters smaller than 0.2mm upon request to meet specialized micro-machining needs.

Why is this tool better for HRC65 materials than regular end mills?

Its nano coating and edge passivation treatment reduce wear and prevent edge failure, which is critical for maintaining precision when cutting hard HRC65 substrates.

Shipping & Order Support

Which shipping methods are available for global delivery?

We offer flexible global shipping via EMS, DHL, TNT, UPS, and sea freight, with real-time tracking provided for all orders to ensure timely delivery.

What is the lead time for large-quantity orders?

1-100 pieces: 2 days;

101-1000 pieces: 9 days;

1001-10000 pieces: 30 days;

Over 10000 pieces: Lead time is negotiable based on production schedules.

Does the supplier offer technical support for custom tool designs?

Yes, our engineering team provides full technical support, from initial design consultation to post-production testing, to ensure ODM/OEM projects meet your exact requirements.

English

English