Product Overview

Crafted from 100% new PCD CARBIDE material, this high precision milling cutter features a diamond coating and 35° helix angle, making it ideal for CNC Machining Centers. Designed to handle high-hardness materials ranging from 45HRC to 65HRC, the tool delivers smooth cutting, wear resistance, and enhanced milling efficiency for micro-processing applications. With a global customer base spanning Azerbaijan, Thailand, and Poland, and a 99.5% positive review rate, this micro-diameter cutting tool stands out as a reliable choice for precision manufacturing.

Key Features & Benefits

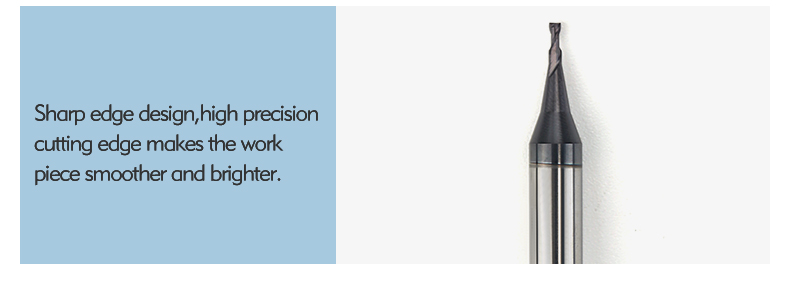

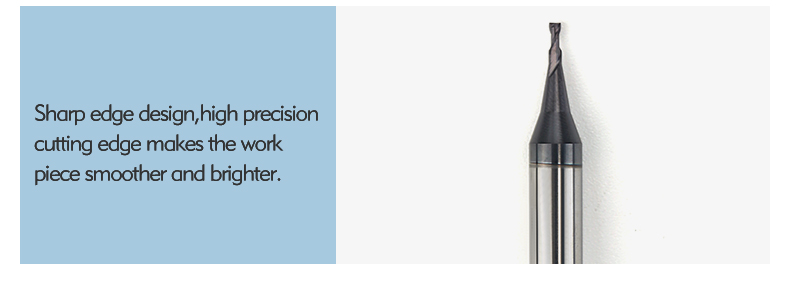

Precision-Engineered Spiral Edge Design

Sharp & Wear-Resistant Spiral Edges

Adopting foreign first-class precision machine tools (TTB/ANCA/DECKEL/HOYMAN/TOP), the spiral edge end mill boasts sharp, wear-resistant cutting edges. This design ensures smooth cutting action, reducing friction and improving overall milling efficiency — a critical advantage for high-precision micro-processing tasks.

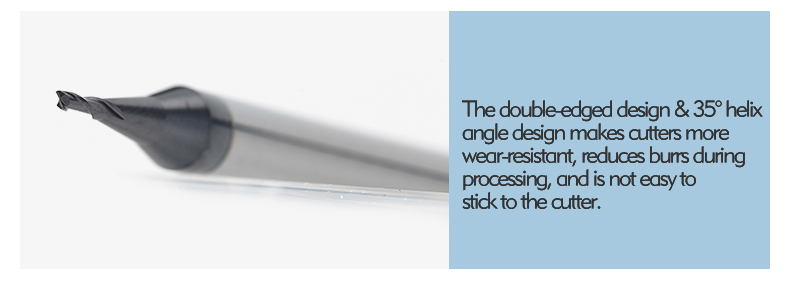

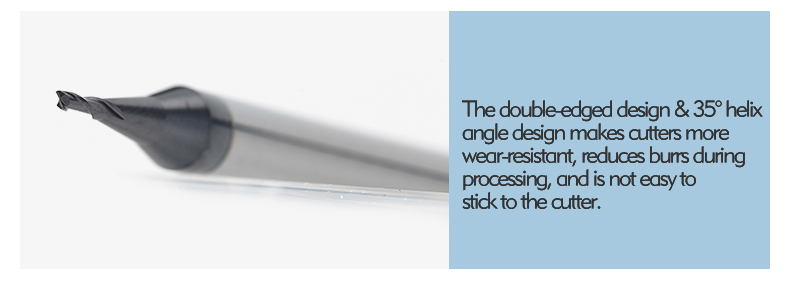

Burr Reduction & Non-Stick Performance

The double-edged structure and 35° helix angle work synergistically to minimize burs during processing. Unlike conventional tools, this micro-diameter flat end mill resists chip adhesion, keeping the cutting edge clean and maintaining consistent performance throughout long production runs.

Premium PCD CARBIDE Material

High Hardness & Stability

Made from top-grade PCD CARBIDE, the tool offers exceptional hardness and dimensional stability. It effortlessly handles materials with HRC ratings of 45, 55, 60, and 65, making it suitable for a wide range of high-hardness workpieces in aerospace, automotive, and precision engineering industries.

Long Service Life

The 100% new material and rigorous quality control ensure superior durability. Compared to standard carbide tools, this wear-resistant end mill delivers a longer service life, reducing tool replacement frequency and lowering production costs.

Diamond Coating Technology

Enhanced Wear Resistance

The diamond coated end mill features a high-performance diamond coating that significantly boosts wear resistance. This coating protects the tool from abrasion during high-speed cutting, extending its lifespan even when processing the hardest materials.

Improved Cutting Smoothness

The diamond coating also reduces surface friction, enabling the tool to glide through workpieces with minimal resistance. This results in smoother, brighter finished surfaces, eliminating the need for secondary polishing and enhancing productivity.

Multi-Flute Options & Versatile Sizes

Flute Customization for Diverse Applications

Offering 2-6 flutes, the tool adapts to diverse milling needs — from roughing to finishing. More flutes mean increased cutting points, improving surface finish, while fewer flutes enhance chip evacuation for deeper cuts.

Micro-Diameter & Customizable Dimensions

With outside diameters ranging from 0.2mm to 20mm, shank diameters of 4-20mm, and overall lengths of 38-150mm, this versatile end mill caters to micro-processing and large-scale milling alike. Custom size options are available to meet unique project requirements.

Project code | Outer diameter | Handle diameter | Flute length | Total length |

BFL-SD-002 | 0.2 | 4 | 0.4 | 50 |

BFL-SD-003 | 0.3 | 4 | 0.6 | 50 |

BFL-SD-004 | 0.4 | 4 | 0.8 | 50 |

BFL-SD-005 | 0.5 | 4 | 1.0 | 50 |

BFL-SD-006 | 0.6 | 4 | 1.2 | 50 |

BFL-SD-007 | 0.7 | 4 | 1.4 | 50 |

BFL-SD-008 | 0.8 | 4 | 1.6 | 50 |

BFL-SD-009 | 0.9 | 4 | 1.8 | 50 |

BFL OEM & Customization Services

Free Laser Marking Customization

LOGO/Specifications/Parameters Marking

We offer free custom laser marking on the tool body, including your brand LOGO, product specifications, or technical parameters. This service enhances brand visibility and simplifies inventory management.

High Precision Marking Quality

Using advanced laser equipment, our markings are clear, durable, and resistant to wear — even during intense cutting operations.

Custom Label & Packaging Solutions

Tailored Label Content

Customize label content to include product details, usage instructions, or branding elements. Our labels are designed for clarity and compliance with international shipping standards.

Optional Packaging Tubes & Boxes

Choose from standard packaging or opt for custom outer packing boxes and packaging tubes to protect the tools during transit. We tailor packaging to your logistics needs.

Tailored Specifications & Coatings

Custom Diameter & Length

Adjust outside diameter, shank diameter, flute length, and overall length to match your specific milling requirements. Our engineering team ensures precise adherence to your dimensions.

Various Coating Options

Beyond diamond coating, we offer alternative coatings (e.g., AlTiN, TiSiN) based on your application needs, such as improved heat resistance or lubricity.

Drawing/Sample-Based Customization

Full Customization Support

We accept drawing-based customization and sample-based customization for special micro-diameter end mills. Whether you need a unique flute design or modified helix angle, our team delivers tailored solutions.

Professional R&D Collaboration

Our experienced R&D team works closely with you to refine designs, ensuring the custom tool meets performance expectations for your target materials and processes.

FAQ

What is the MOQ for the BFL Micro-diameter Flat End Mill?

The minimum order quantity (MOQ) is 10 pieces, which balances small-batch trials and cost-effectiveness for large-scale production. For orders exceeding 100 pieces, contact us for negotiated pricing.

Which materials can this PCD CARBIDE end mill process?

It is optimized for high-hardness materials with HRC ratings of 45, 55, 60, and 65, including alloy steels, hardened steels, and other tough workpieces requiring precision micro-milling.

What is the lead time for standard and custom orders?

Standard orders (1-10 pieces): 7 working days

Medium orders (11-100 pieces): 14 working days

Large/custom orders (>100 pieces): Negotiable based on customization complexity

Which shipping methods are available?

We partner with UPS, Fedex, DHL, TNT, EMS, and offer sea freight for bulk orders. Shipping costs are optimized based on your location and order volume.

Can I request a sample before placing a large order?

Yes! We provide sample orders (minimum 10 pieces) to help you test the tool’s performance. Contact our sales team to arrange sample delivery and technical support.

English

English