Product Overview

BFL solid carbide end mill with 4 flute corner radius is a precision-engineered CNC cutting bit designed for high-efficiency machining of materials ranging from 45HRC to 65HRC hardness. Crafted from 100% new solid carbide material, this end mill delivers exceptional durability, chip evacuation, and surface finish for a wide array of CNC machining center applications. Available with multi-coating options including AlTiN, TiAlN, TiSiN, TiN, and DLC, it adapts seamlessly to diverse workpiece requirements, reducing tool wear and extending service life. As a hot-selling product from a 17-year Chinese factory, BFL end mill supports full OEM/ODM customization, making it the ideal choice for manufacturers in automotive, mold making, and precision machinery industries.

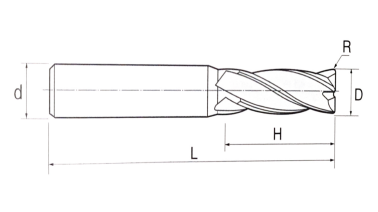

Product Specifications

Feature Category | Details |

Core Material & Hardness Resistance | 100% new solid carbide; compatible with 45HRC, 55HRC, 60HRC, 65HRC workpieces |

Structural Design | 2-4 flute options; customizable corner radius (e.g., R0.015, R0.02); multiple diameter specifications (1/8", 3/16", 1/4", 5/16" etc.) |

Coating Options | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO – tailored for different machining scenarios |

Applicable Equipment | CNC machining centers; processed by TTB/ANCA/DECKEL/HOYMAN/TOP machinery |

Customization Support | OEM/ODM, drawing-based customization, sample-based customization; free samples available |

MOQ | 10 pieces |

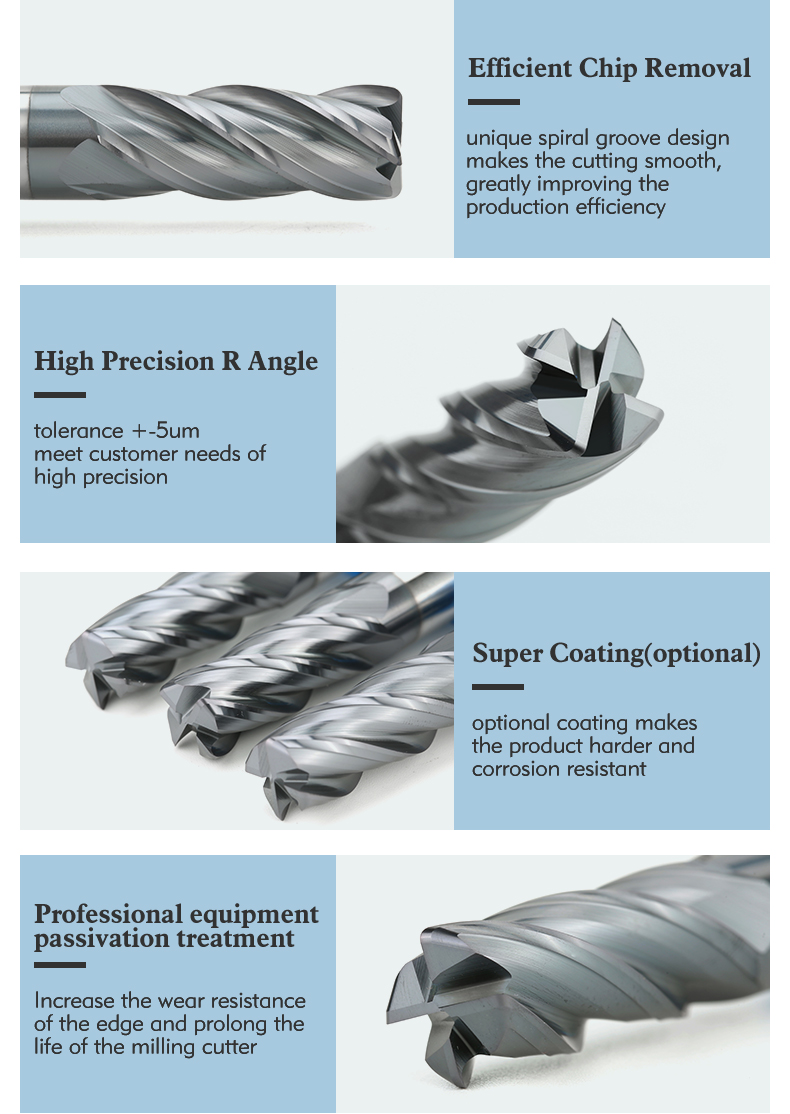

Key Features

Solid Tungsten Carbide Construction

Made of high-purity tungsten carbide, the tool features superior hardness and impact resistance, extending tool life by up to 30% compared to conventional cutting tools. It maintains sharp edges even under high-speed machining conditions, reducing tool change frequency and production downtime.

Multi-Coating Options for Versatility

We offer a range of professional coatings including TiSiN, AlTiN, TiAlN, and bronze coating. Each coating is tailored to specific machining needs—TiSiN coating for high-temperature resistance, AlTiN coating for enhanced hardness, and bronze coating for reduced friction when cutting aluminum.

Customizable Design to Meet Unique Needs

Since 2013, BFL has focused on custom carbide tools, and our round nose end mill supports full customization based on your drawings or samples. We can adjust flute quantity (2/4/6 flutes), cutting diameter, neck length, and coating type to match your exact machining requirements.

Strict Quality Control Assurance

Every round nose end mill undergoes rigorous inspection with advanced testing equipment before delivery. Our QC process covers dimensional accuracy, coating adhesion, and cutting performance, ensuring only qualified products reach our customers.

Supplier Advantages & Service Guarantee

Application Scenarios & User Benefits

High-hardness Material Machining: Ideal for 45-65HRC steel, alloy steel, and hardened metal processing; reduces tool replacement frequency by 30% compared to conventional end mills.

Precision Manufacturing: Perfect for mold making, automotive parts, and precision machinery components; the 4 flute corner radius design ensures smooth surface finish and avoids workpiece edge chipping.

Bulk Production Lines: Stable performance and customizable specifications meet the needs of large-scale manufacturing; OEM service helps brands build exclusive tool solutions.

Call to Action

Get a Custom Quote Now: Contact our sales team to discuss your specific machining requirements and get a tailored price.

Claim Free Samples: Test the performance of BFL solid carbide end mill before placing bulk orders – limited stock available!

Send Inquiry: Click the "Send Inquiry" button to start your cooperation with a 17-year certified CNC tool factory.

FAQ

What is the MOQ for BFL solid carbide end mill?

The minimum order quantity is 10 pieces, and we offer favorable prices for bulk orders.

Can I get free samples to test the quality?

Yes, free samples are available. You only need to cover the shipping cost in most cases.

Which coating is suitable for high-temperature machining?

AlTiN coating is recommended for high-temperature machining scenarios, as it has excellent heat resistance and oxidation resistance.

How long is the delivery time for custom end mills?

For custom orders with drawings, the delivery time is negotiable based on the complexity of the specifications, usually 10-15 working days.

English

English