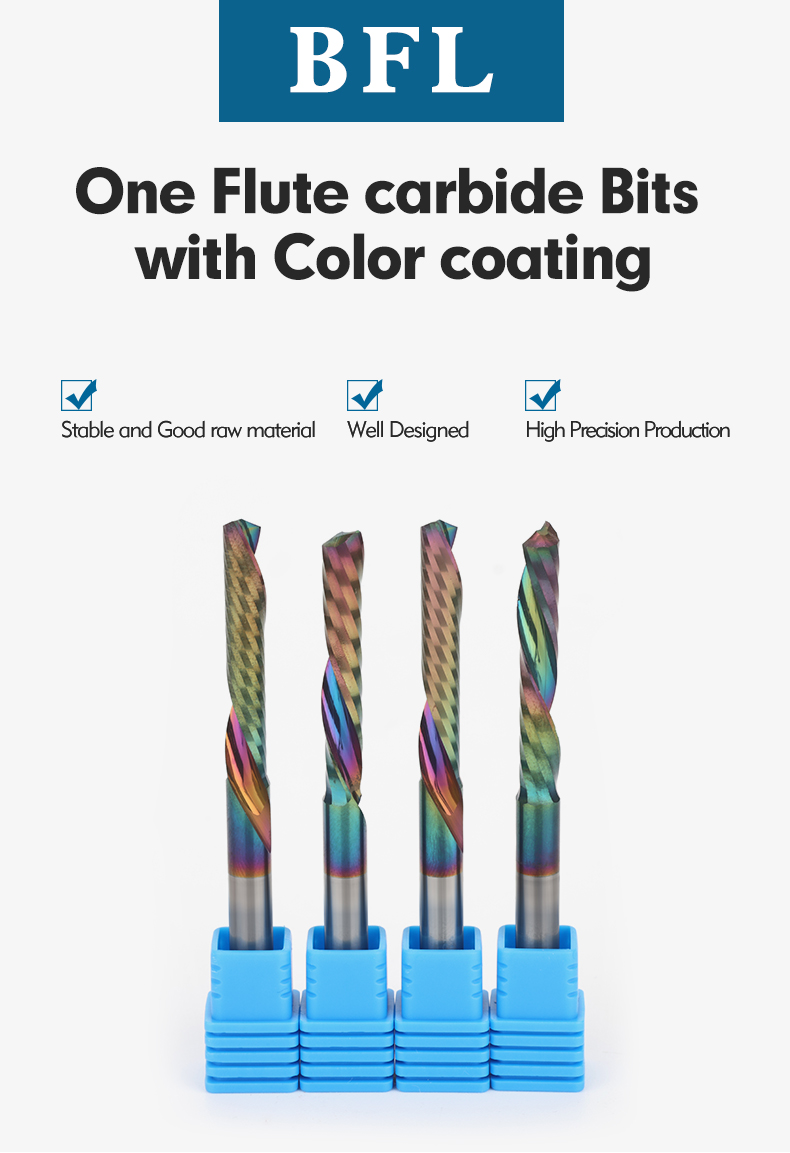

Product Overview

Manufactured by Changzhou North Carbide Tool Co., Ltd. – a verified custom manufacturer with 17 years of expertise – this end mill combines Solid Carbide Material and advanced coating technology to ensure durability and efficiency. With a 99.5% positive review rate and exports to Azerbaijan, Thailand, and Poland, it’s a reliable solution for machinists working with plywood, wood, and soft plastics. Unlike standard end mills, its down cut design presses material downward during cutting, making it ideal for preventing top-side tearing in plywood – a common pain point in woodworking.

Key Features & Benefits

Sharp Cutting Edge for Consistent Quality

The Sharp Cutting Edge undergoes a specialized tip treatment, resisting breakage even during high-frequency use. This feature ensures plywood workpieces remain burr-free, reducing post-processing time and improving production efficiency.

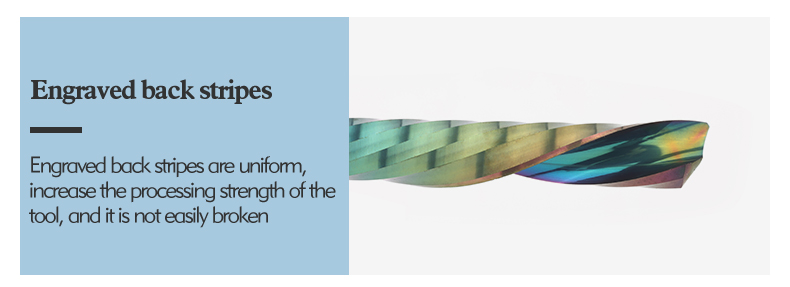

Large Chip Flute Design for Smooth Operation

Equipped with a Large Chip Flute Design, the end mill enables seamless chip removal. This minimizes clogging, lowers operational noise, and maintains a clean cutting path – critical for preserving the integrity of plywood surfaces and extending tool life.

AlTiN Coating for Heat Resistance

Featuring AlTiN Coating (with optional TiAlN/TiSiN/Naco/Diamond coatings), the tool offers exceptional heat stability (oxidation temperature: 900°C) and a low friction coefficient (0.35). This makes it suitable for high-speed dry cutting of plywood, as it resists thermal wear and maintains cutting precision.

High Flexural Strength for Durability

Crafted from premium solid carbide (e.g., HRC65 grade uses Sandvik H10F), the end mill boasts a flexural strength of up to 4300 N/mm². This durability ensures long-term performance, reducing tool replacement costs for frequent plywood machining tasks.

Product Specifications

Specification | Details |

Product Name | BFL Carbide Single Flute Down Cut End Mill |

Brand | BFL, OEM |

Material | 100% Solid Carbide (YG10X/YL10.2/K44/Sandvik H10F) |

Coating Options | AlTiN, TiAlN, TiSiN, Naco, DLC, Diamond |

Number of Flutes | 1 (Single Flute) |

HRC Hardness Rating | 45/55/60/65 Degrees |

Shank Diameter | 4-20 mm |

Suitable Materials | Plywood, Wood, Plastic, Acrylic, Soft Metals |

MOQ | 10 Pieces |

Lead Time | 7 days (1-100 pieces); Negotiable (>100 pieces) |

Shipment Options | UPS, Fedex, DHL, TNT, EMS, Sea Freight |

BFL OEM & Customization Services

BFL prioritizes flexibility with comprehensive OEM Services to meet unique customer needs:

Free Laser Marking: Customize the tool body with your logo, specifications, or parameters for brand recognition.

Custom Packaging: Tailor outer boxes and optional packaging tubes to align with your brand standards.

Coating Customization: Select coatings (e.g., Diamond for high-precision cuts) based on your machining requirements.

Free Samples: Request free samples to test compatibility with your plywood machining processes before bulk orders.

FAQ

Is BFL a factory or trader?

BFL is a verified manufacturer with its own factory, equipped with imported machines (TTB/ANCA/DECKEL/HOYMAN/TOP) for precision production and quality control.

What is the MOQ for this end mill?

The minimum order quantity is 10 pieces, with flexible lead times to accommodate small-batch or large-scale orders.

Can this tool be used for materials other than plywood?

Yes, it’s versatile for wood, plastic, acrylic, and soft metals, making it a general-purpose solution for CNC machining.

How does the down cut design benefit plywood machining?

The down cut design presses plywood downward during cutting, preventing top-side splintering and ensuring a smooth finish – eliminating the need for sanding or touch-ups.

English

English