Product Overview

Constructed from high-purity solid carbide, this cutter delivers long tool life and consistent performance, supported by Changzhou North Carbide Tool Co., Ltd.’s status as a top machining factory (16 years of experience, US$1.6M+ online revenue). It meets EU 2015/863 standards and offers flexible customization to fit diverse industrial needs.

Key Features & Benefits

Ultra-Low Friction DLC Coating

The DLC coating (hardness up to 2000 HV) has a friction coefficient <0.1, preventing material adhesion (critical for aluminum machining) and resisting chemicals—greatly extending tool life.

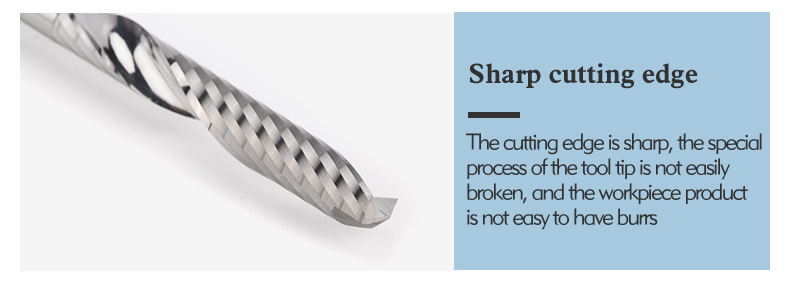

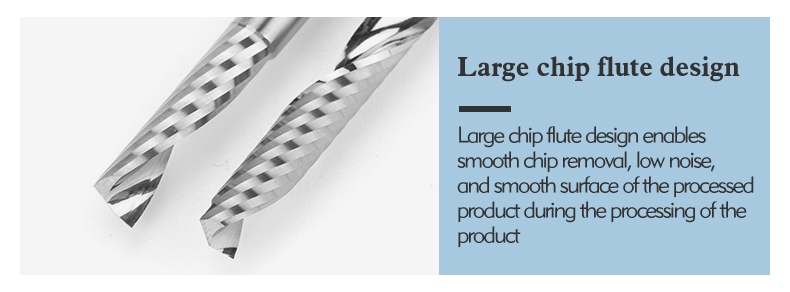

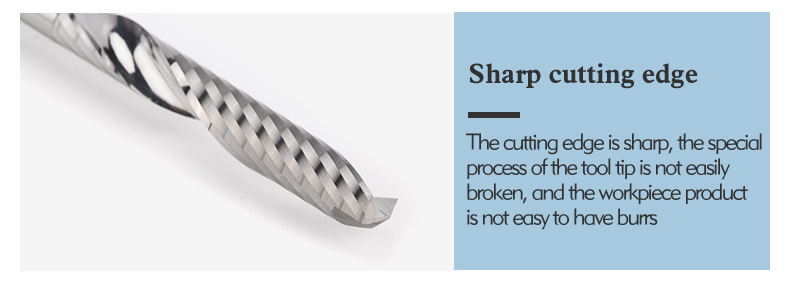

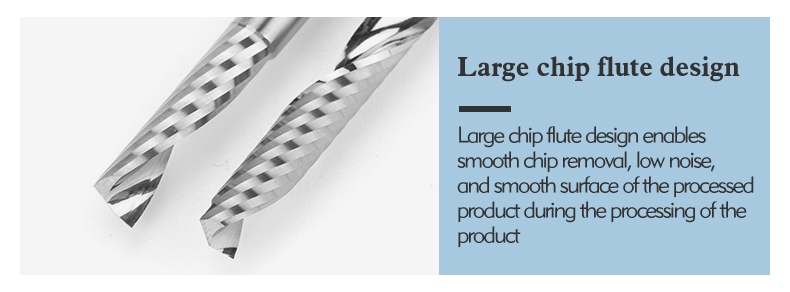

The single flute geometry reduces cutting forces and heat buildup, making it perfect for precision machining of thin-walled parts or soft materials where chip clogging is a risk.

High HRC Compatibility

Capable of handling materials up to 65 HRC, the cutter excels in machining hardened steels and alloys without chipping or premature wear.

Made from high-density micro-grain carbide, the tool offers exceptional toughness and dimensional stability, ensuring consistent cutting performance across batches.

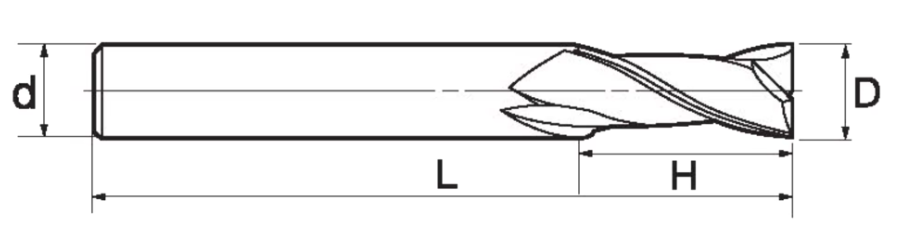

Product Specifications

Product Code | Flute Diameter (mm) | Overall Length (mm) | Shank Diameter (mm) | HRC Rating | Coating Type | Target Material |

BFL-DLC-S005 | 0.5 | 50 | 3 | 45-65 HRC | DLC | Aluminum |

BFL-DLC-S010 | 1.0 | 50 | 4 | 45-65 HRC | DLC | Stainless Steel |

BFL-DLC-S020 | 2.0 | 60 | 6 | 45-65 HRC | DLC | Carbon Steel |

BFL-DLC-S030 | 3.0 | 75 | 8 | 45-65 HRC | DLC | Mould Steel |

BFL-DLC-S050 | 5.0 | 100 | 10 | 45-65 HRC | DLC | Hardened Alloys |

BFL OEM & Customization Services

Coating Customization

Adjust DLC coating thickness (0.5-2μm) to enhance wear resistance for heavy-duty cutting or reduce friction for precision tasks.

Customize flute diameter (0.1-5.0 mm), overall length (50-200 mm), or shank diameter (3-10 mm) based on your drawings—ideal for specialized CNC machines.

Brand & Packaging Custom

Add custom graphics, barcodes, or brand labels to the tool. We also design packaging (e.g., vacuum-sealed packs, custom cartons) for safe international shipping.

Develop single flute cutters for unique materials (e.g., titanium) or processes (e.g., deep-hole machining) with optimized flute geometry.

FAQ

How does DLC coating compare to TiAlN for aluminum machining?

DLC coating has a lower friction coefficient, preventing aluminum adhesion to the tool—unlike TiAlN, which may cause chip buildup.

Is this cutter suitable for high-speed machining?

Yes, it supports high-speed machining (up to 8000 rpm for aluminum) thanks to its DLC coating and single flute design, which reduce heat and vibration.

What quality checks do finished cutters undergo?

Each cutter undergoes dimensional testing, hardness verification, and coating adhesion checks—all documented under ISO 9001:2008 standards.

What shipping methods are available for international orders?

We partner with UPS, FedEx, DHL, TNT, and EMS for fast delivery. Sea freight is available for bulk orders at competitive rates.

What is the lead time for a fully customized cutter?

Standard custom orders take 7-10 days; complex designs (e.g., special flute shapes) take 12-15 days, with real-time production updates provided.

English

English