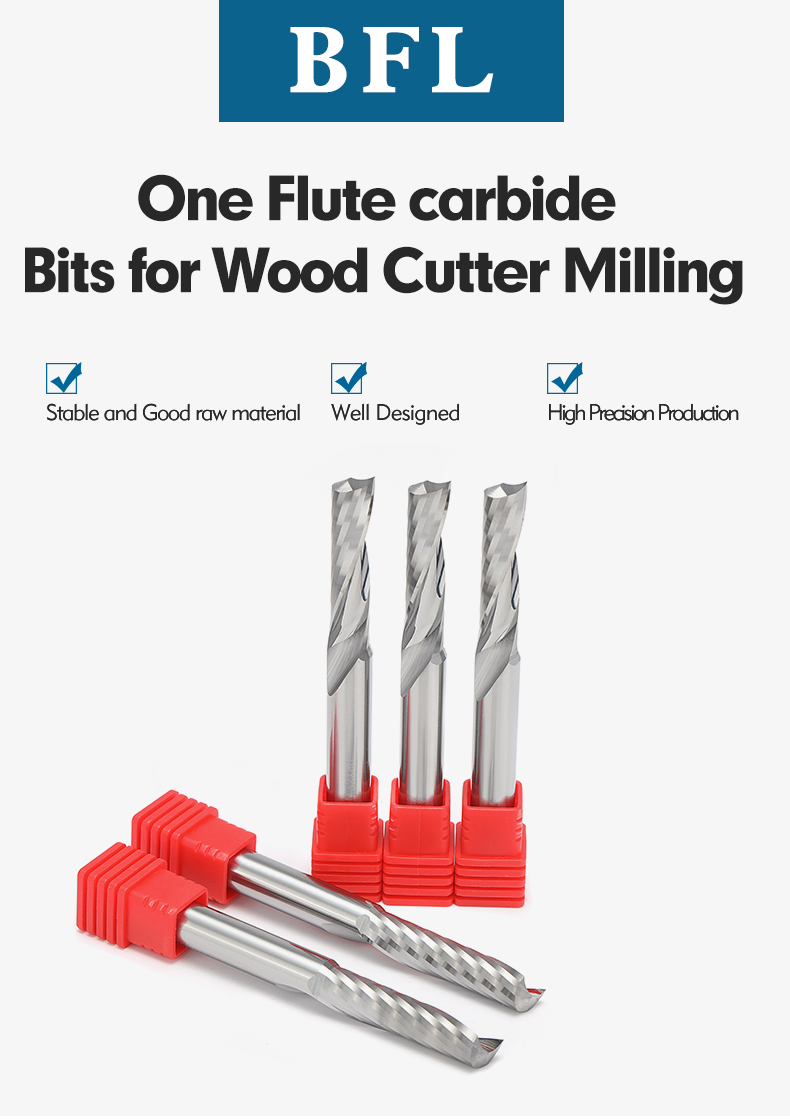

Product Overview

Produced by Changzhou North Carbide Tool Co., Ltd. – an 18-year experienced manufacturer with ISO9001 and SGS certifications – this tool addresses acrylic’s sensitivity to heat and friction. As a dual manufacturer-trader with a 99.5% positive review rate, BFL exports to global markets and uses 5-axis CNC grinding machines (Switzerland RPL-LOMTIC, Germany WALTER) for consistent precision. Whether for acrylic signage, displays, or components, this single flute end mill ensures crystal-clear finishes without compromising material integrity.

Key Features & Benefits

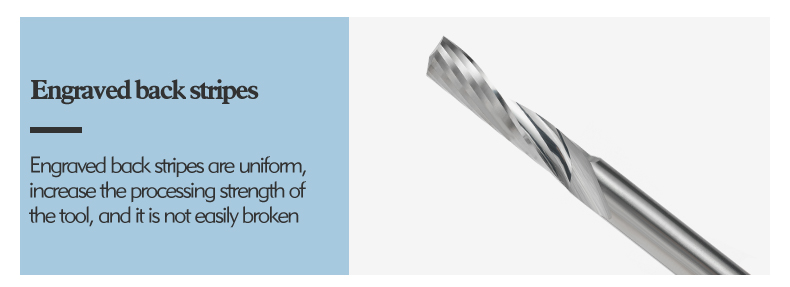

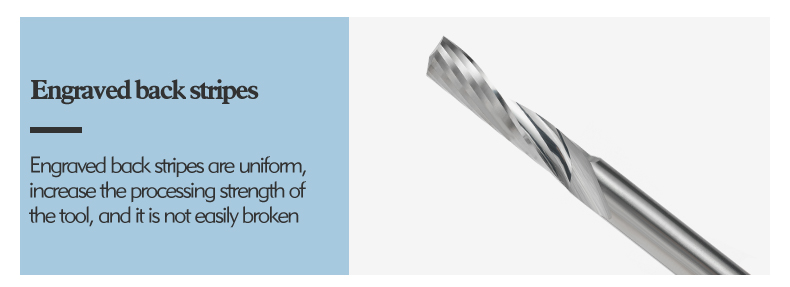

Engraved Back Stripes for Enhanced Stability

The Engraved Back Stripes are uniformly milled to boost tool strength, preventing breakage during heavy acrylic cutting. This stability ensures consistent depth control, critical for intricate acrylic designs.

TiSiN/Diamond Coating for Precision

Offering TiSiN Coating (hardness: 4300 HV) and Diamond Coating options, the end mill resists scratches and oxidation (TiSiN oxidation temp: 1000°C). This preserves acrylic’s transparency and ensures long tool life in high-demand applications.

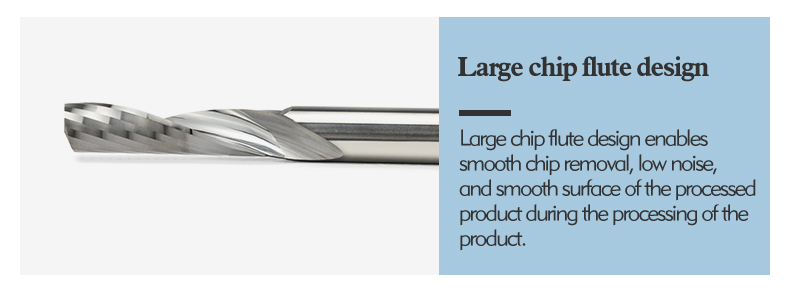

Low Friction Coefficient for Heat Control

With a friction coefficient as low as 0.25 (TiSiN coating), the tool minimizes heat generation. This avoids thermal damage to acrylic (which causes clouding) and enables smooth, quiet machining for delicate projects.

High-Precision Production for Uniformity

Each end mill undergoes strict inspection, with a tolerance of -0.02 mm and exact helix angles. This precision guarantees uniform cuts across acrylic workpieces, reducing material waste and ensuring batch consistency.

Product Specifications

Specification | Details |

Product Name | BFL Carbide Single Flute End Mill for Acrylic |

Brand | BFL, DOHRE, OEM |

Material | 100% Solid Carbide (YG10X/YL10.2/K44/Sandvik H10F) |

Coating Options | AlTiN, TiAlN, TiSiN, Naco, DLC, Diamond |

Number of Flutes | 1 (Single Flute) |

HRC Hardness Rating | 45/55/60/65 Degrees |

Shank Diameter | 4-20 mm |

Overall Length | 38-150 mm |

Suitable Materials | Acrylic, Plastic, Wood, Metal, Composites |

MOQ | 20 Pieces |

Lead Time | 3 days (in-stock samples); 7-10 days (small non-standard); 30 days (bulk) |

Shipment Port | Shanghai Port |

BFL OEM & Customization Services

BFL’s Custom Tool Design capabilities cater to unique acrylic machining needs:

Drawing/Sample-Based Customization: Develop non-standard tools using your technical drawings or samples (available since 2013).

R&D Collaboration: Work with BFL’s R&D team to create tools tailored to your specific acrylic cutting processes.

Branded Labeling: Customize labels and packaging (plastic tubes, outer boxes) to match your brand identity.

Traceable Marking: Add batch numbers or logos via laser marking for inventory tracking.

FAQ

Does BFL offer discounted shipping?

While free shipping isn’t available, BFL provides discounted rates for large orders through partner couriers (UPS, Fedex, DHL).

Can BFL produce tools for unique acrylic projects?

Yes, BFL specializes in custom carbide tools – provide drawings or samples, and the team will develop a solution.

What payment methods are accepted?

BFL accepts Alipay, Paypal, Western Union, ESCROW, Trade Assurance, and UnionPay. A 30% deposit (balance before shipping) is optional.

Why choose this end mill for acrylic?

Its single flute design and specialized coatings prevent acrylic scratching and clouding, while high precision ensures the material’s transparency is preserved – ideal for high-end acrylic products.

English

English