Product Overview

Produced by Changzhou North Carbide Tool Co., Ltd. — a 17-year experienced factory with 99.5% customer satisfaction — this end mill excels in durability and cutting efficiency. It uses premium solid carbide as the base material and is enhanced with a DLC (Diamond-Like Carbon) coating, making it ideal for high-speed cutting on various wood types. Designed for CNC milling machines, its single straight flute structure ensures smooth cuts and efficient chip evacuation, fitting professional woodworking factories, furniture lines, and custom workshops. With OEM, ODM, and OBM support, it can be customized to meet specific machining needs, boosting versatility.

Key Features & Benefits

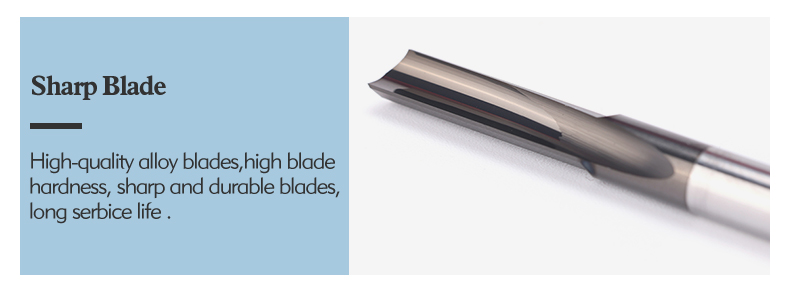

Premium Solid Carbide Material

Crafted from high-quality solid carbide, the end mill offers exceptional hardness and wear resistance, enduring high-speed cutting without deformation or blunting. This extends its service life, reduces tool replacement frequency, and lowers production costs.

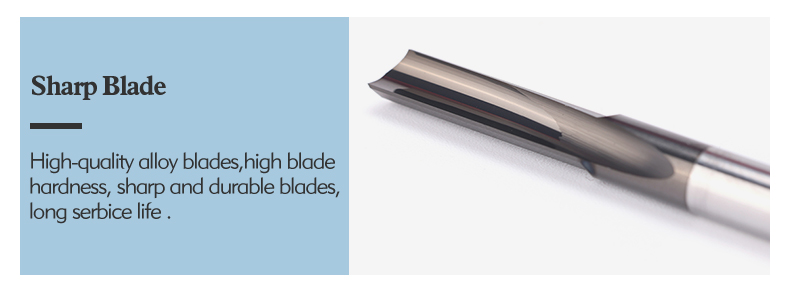

Advanced DLC Coating Technology

The DLC coating forms a low-friction protective layer on the tool surface, minimizing friction between the tool and workpiece during cutting. This reduces heat generation, prevents chip adhesion, and ensures clean, precise wood cuts. It also enhances corrosion resistance for long-term use in diverse environments.

Single Straight Flute Design

Optimized for woodworking, the single straight flute enables efficient chip evacuation. Unlike spiral flutes, it discharges wood chips quickly to avoid jamming — which can damage tools or mar workpiece surfaces — ensuring stable performance and improved wood finish quality.

High Precision & Versatile HRC Ratings

Built to high-precision standards, the end mill guarantees consistent cutting dimensions and meets strict tolerances. It comes in multiple HRC ratings (45HRC, 55HRC, 58HRC, 60HRC, 65HRC), adapting to softwoods, hardwoods, and dense wood materials for flexible woodworking solutions.

Customizable Options & Reliable Certification

Supported by OEM, ODM, and OBM services, it can be customized in diameter, overall length, and other specs. The product holds ISO and TUV certifications, complying with international quality standards and building customer trust in its reliability.

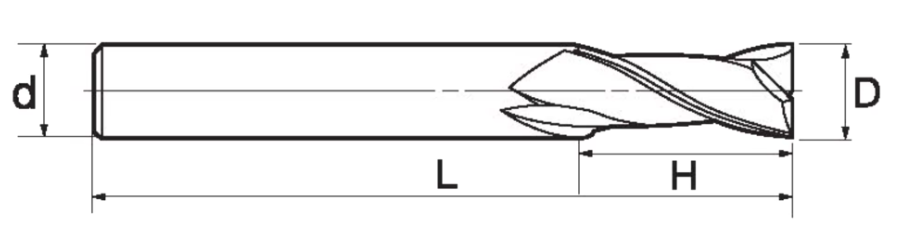

Product Specifications

Specification Item | Details |

Product Name | BFL Solid Carbide DLC Coated Single Straight Flute End Mill for Wood |

Brand | BFL |

Material | Solid Carbide |

Coating | DLC (Diamond-Like Carbon) |

HRC Hardness Rating | 45HRC, 55HRC, 58HRC, 60HRC, 65HRC |

Flute Number | 1 (Single Straight Flute) |

Diameter Range | 1–20mm |

Overall Length Range | 50–150mm |

Machine Type | CNC Milling Machine |

Application | High-Speed Wood Cutting |

Certifications | ISO, TUV |

Customization Support | OEM, ODM, OBM |

MOQ | 10 pieces |

BFL OEM & Customization Services

Flexible Customization Types

BFL offers multiple customization options to match diverse customer needs:

Light Customization: Adjust basic specs like diameter (1–20mm) and overall length (50–150mm) without major design changes.

Design-to-Drawing Customization: Create end mills based on customer-provided technical drawings, ensuring alignment with specific machining workflows.

Sample-Based Customization: Replicate or optimize end mills using customer-provided samples, ideal for replacing legacy tools.

On-Demand Customization: Develop fully tailored solutions (e.g., special flute designs, coating tweaks) for unique woodworking scenarios.

Customization Process

Customer submits requirements (drawings, samples, or specs).

BFL provides a detailed quote and technical plan within 2–3 business days.

After confirmation, a prototype is produced (if needed) for customer approval.

Mass production begins, with quality checks at each stage.

FAQ

What is the minimum order quantity (MOQ) for this end mill?

The MOQ is 10 pieces. For bulk orders (>100 pieces), contact BFL for personalized pricing and delivery terms.

How long does delivery take to the US?

Delivery times vary by order quantity: 7 days for 1–10 pieces, 10 days for 11–100 pieces, and will be confirmed for orders over 100 pieces. Shipping methods include sea, air, and express.

Does the end mill come with a warranty?

Currently, the product does not include a warranty, but BFL ensures strict quality control (ISO/TUV certified) to minimize defects. For issues like material flaws, contact BFL within 7 days of receipt for support.

English

English