Product Overview

This tool excels in machining a wide range of materials, including metals, plastics, wood, and acrylics, making it ideal for automotive, mold, and plastic processing industries. Its unique long neck design enables deep cavity machining without tool interference, while the short flute structure enhances rigidity and reduces vibration during high-speed cutting. Crafted from 100% new solid carbide and available with multiple advanced coatings, the BFL Flat End Mill delivers exceptional durability and precision, even when processing materials up to HRC65 hardness.

Key Features & Benefits

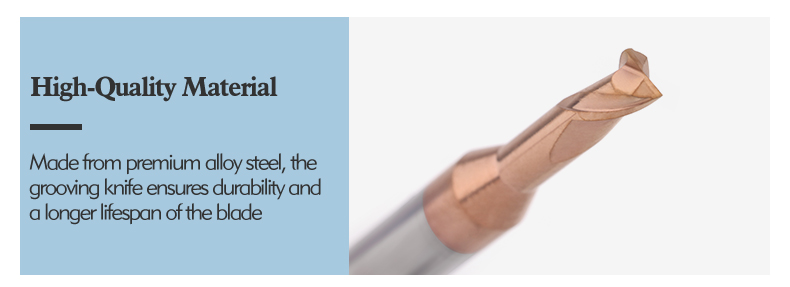

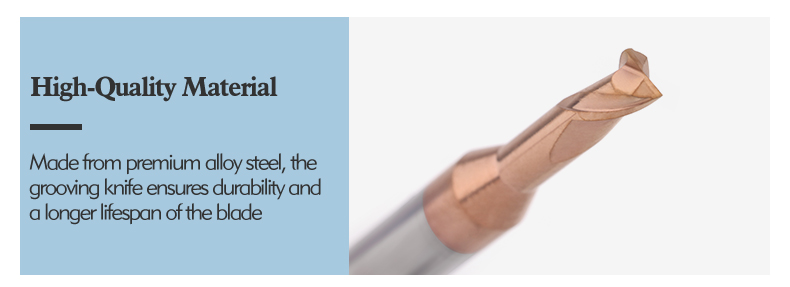

Premium Solid Carbide Material for Maximum Durability

Made from high-grade carbide materials (e.g., Sandvik H10F for HRC65 applications), the BFL Carbide End Mill offers a flexural strength of 4300N/mm². This ensures resistance to wear and breakage, extending tool life by 30% compared to standard carbide cutters. The fine-grain structure (0.5-0.7um) further enhances cutting sharpness, delivering smooth surface finishes on workpieces.

Multi-Coating Options for Versatile Machining

The tool supports a variety of industry-leading coatings, including AlTiN Coated End Mill, TiAlN, TiSiN, DLC, and NANO coatings. Each coating is tailored to specific needs:

AlTiN: High heat stability (900°C oxidation temp) for high-speed dry cutting;

TiSiN: 4300HV hardness, ideal for heavy cutting and high-hardness materials (HRC60+);

DLC: Low friction coefficient (0.25) to prevent chip adhesion on plastic/wood workpieces.

Long Neck Design for Deep-Cavity Applications

The long neck carbide cutter features an extended shank that reaches deep cavities or narrow spaces without tool-body contact. This design is critical for mold machining and complex part production, where standard end mills often fail to access hard-to-reach areas.

Short Flute Structure for Enhanced Stability

The short flute milling tool minimizes tool overhang, reducing vibration during cutting. This improves machining accuracy (tolerance as low as -0.02mm) and prevents chatter marks on workpieces, making it suitable for precision components like automotive parts.

Wide Hardness Compatibility (HRC45-65)

From soft plastics (HRC45) to hardened mold steel (HRC65), the BFL HRC65 Carbide Cutter adapts to diverse materials. This versatility eliminates the need for multiple tools, lowering production costs for manufacturers.

Product Specifications

Parameter | Details |

Brand Name | BFL |

Product Type | 2 Flutes Flat End Mill (optional 2-6 Flutes) |

Material | 100% Solid Carbide (YG10X, YL10.2/WF25, Germany K44/K40, Sandvik H10F) |

HRC Compatibility | HRC45 / HRC55 / HRC60 / HRC65 |

Shank Diameter | 4-20mm |

Coating Types | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO |

MOQ | 10 Pieces |

Lead Time | 7 days (1-10 pieces); Negotiable (>10 pieces) |

Tolerance | -0.02mm |

Applicable Materials | Metals, Plastics, Wood, Acrylics |

BFL OEM & Customization Services

BFL offers comprehensive custom carbide end mill solutions to meet unique machining needs:

OEM Support: Full OEM services (logo, packaging, specifications) are available — ideal for brands seeking private-label milling tools.

Custom Dimensions: Shank diameter (4-20mm), flute length, and neck length can be tailored via drawings or samples.

Free Samples: Test samples are provided to verify performance before bulk orders.

Precision Production: Manufactured with imported machines (TTB/ANCA/DECKEL), ensuring consistent quality across batches.

FAQ

Are you a direct manufacturer of BFL Carbide End Mills?

Yes, we are a professional manufacturer with a 17-year history in carbide tools. Our factory is equipped with advanced CNC grinding machines and strict quality inspection systems (SGS, ISO9001 certified).

Can I request a custom coating for specific materials?

Absolutely. We can customize coatings (e.g., TiSiN for stainless steel) based on your machining requirements. Simply share your material type and cutting parameters, and our team will recommend the optimal coating.

What shipping methods do you provide?

We ship via UPS, FedEx, DHL, TNT, EMS, or sea freight. For orders to China-based forwarders, we offer free local delivery to your designated warehouse.

How do you ensure product quality?

Each BFL Carbide Milling Tool undergoes 100% inspection (helix angle, tolerance, coating adhesion) before shipment. We also provide a quality guarantee — defective tools will be replaced free of charge.

English

English