Product Overview

Under the BFL brand, this tool combines an extended neck structure with a ball nose tip, delivering unmatched access to complex workpieces and superior surface finishes. Certified with ISO9001:2008 and boasting a 99.5% positive review rate in markets like Brazil, Canada, and South Korea, our Long Neck End Mill is the go-to choice for demanding machining tasks.

Designed for mold making, die casting, aerospace component manufacturing, and intricate 3D machining, the BFL Ball Nose Router Bit excels in deep grooves, narrow slots, and curved surface processing. The extra-long neck design reaches into hard-to-access areas, while the ball nose tip ensures smooth contouring and chamfering, eliminating the need for secondary finishing operations.

Key Features & Benefits

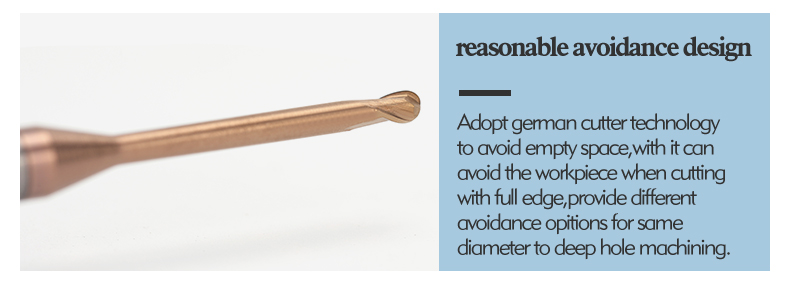

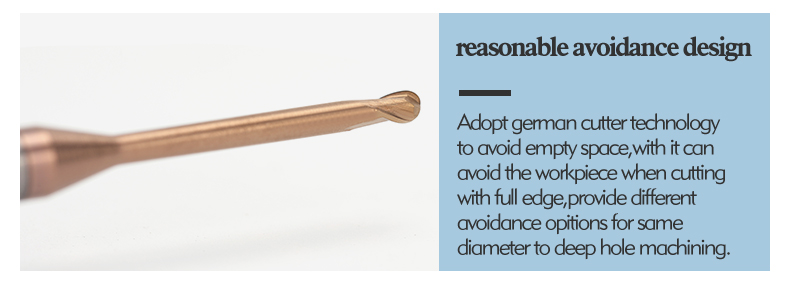

Extended Long Neck for Deep Machining

The extra-long neck structure of our Carbide Long Neck End Mill provides exceptional reach for deep cavities and narrow slots, enabling machining of complex workpieces without tool interference. This design maintains cutting precision and stability even in deep groove areas, ensuring consistent results across high-volume production.

Precision Ball Nose Tip for Contour Machining

The ball nose tip is optimized for 3D contour milling and precision engraving, easily handling curved surfaces, fillets, and intricate patterns. It delivers a burr-free, smooth finish that reduces post-machining cleanup, saving time and labor costs for your operations.

Ultra-Fine Grain Tungsten Carbide Body

Crafted from premium ultra-fine grain tungsten carbide, the tool offers superior rigidity, wear resistance, and anti-vibration performance. This material withstands high cutting temperatures and heavy loads, extending tool life and ensuring reliability in continuous machining.

Multi-Coating Solutions for Versatility

Select from AlTiN, TiAlN, TiSiN, TiN, DLC, or NANO coatings to enhance tool performance for specific materials. Each coating improves lubricity, reduces friction, and prevents chip adhesion, making the tool suitable for hardened steels (up to 65HRC), aluminum alloys, and non-ferrous metals.

Customer-Centric Quality & Support

As a direct manufacturer, we conduct strict quality inspection for every BFL Ball Nose End Mill. Our 5.0-star rated supplier service and 4.9/5 on-time shipment record guarantee a seamless purchasing experience, with dedicated support for customization and technical inquiries.

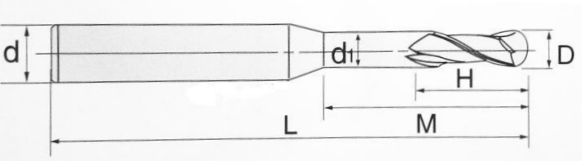

Product Specifications

Specification | Details |

Brand Name | BFL, OEM |

Product Type | Long Neck Ball Nose End Mill |

Material | Ultra-Fine Grain Tungsten Carbide |

Coating Options | AlTiN, TiAlN, TiSiN, TiN, DLC, NANO |

HRC Rating | 45/55/60/65 Degrees |

Flute Quantity | 2-4 Flutes |

Shank Diameter | 4-20mm |

Neck Length | Customizable (Standard: Extended for Deep Access) |

Ball Nose Radius | Matching Shank Diameter (e.g., 6mm Shank = 3mm Radius) |

Standard Sizes | 4mm, 6mm, 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm |

Overall Length | 38-150mm |

MOQ | 10 Pieces |

Free Samples | Available |

BFL OEM & Customization Services

Tailored Tool Solutions

We specialize in drawing-based customization, sample-based customization, and full customization to meet your unique machining requirements. Whether you need a specific neck length, ball nose radius, or coating type, our engineering team delivers precise, project-specific solutions.

Branding & Packaging Customization

Free Laser Marking: Personalize the tool body with your LOGO, specifications, or parameters for brand visibility and traceability.

Custom Labels: Design labels with your company details, product instructions, or compliance certifications (e.g., ISO).

Packaging Options: Choose custom outer boxes or shockproof packaging tubes to protect the tool during shipping and storage.

Flexible OEM/ODM Cooperation

Our OEM & ODM services support small-batch customization and large-scale production. We collaborate closely with you to ensure the final product aligns with your brand standards, performance needs, and market demands.

FAQ

What is the maximum machining depth of the BFL Long Neck Ball Nose End Mill?

The maximum machining depth depends on the customizable neck length. Standard models offer extended reach, and we can tailor the neck length to your specific project requirements (contact us for detailed specifications).

Can I customize the ball nose radius for specific contour needs?

Yes, we provide custom ball nose radius options. Share your drawings or desired dimensions, and our team will design the tool to match your contour machining requirements.

Which coating is best for high-speed machining of aluminum?

DLC or TiAlN coatings are recommended for aluminum, as they reduce friction and prevent chip welding, ensuring smooth cutting and extended tool life.

How long does it take to receive a fully customized order?

For standard customization (e.g., LOGO marking, label design), lead times are 30 days for 1-10 pieces. For complex customization (e.g., neck length, ball nose radius), lead times are negotiable based on design complexity.

Is the tool compatible with CNC routers and milling machines?

Yes, the BFL Long Neck Ball Nose End Mill is compatible with most standard CNC routers and milling machines, offering versatile integration into your existing production line.

English

English