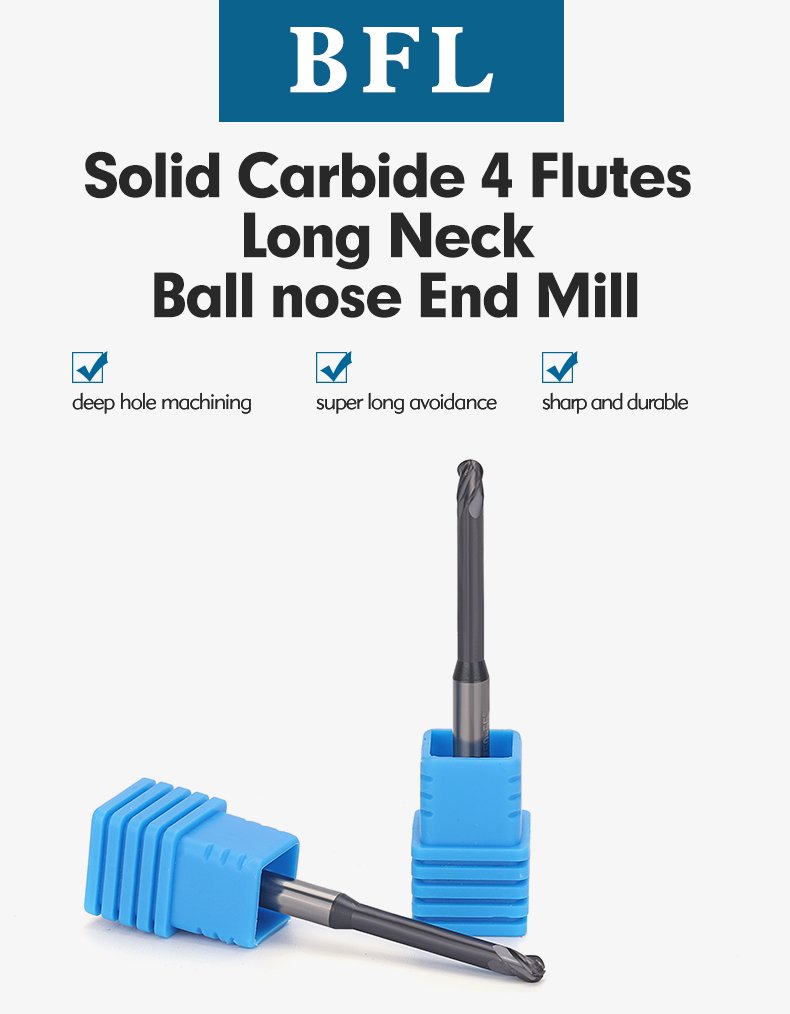

Product Overview

Introduction to BFL Carbide Long Neck

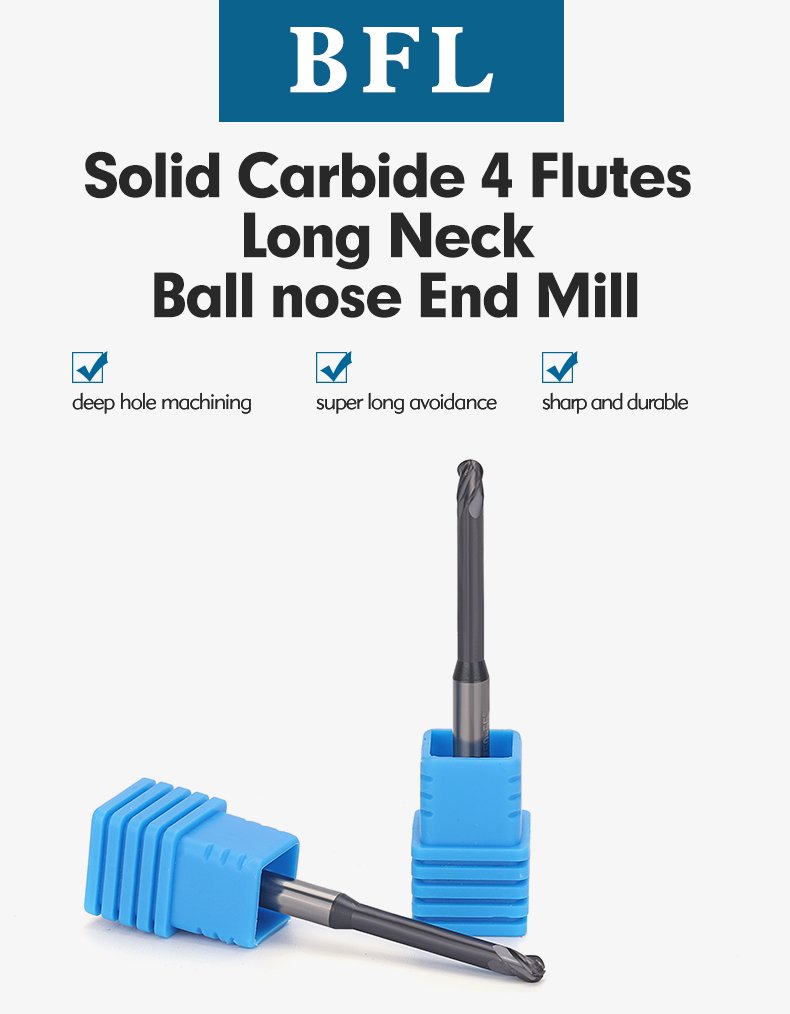

The BFL High-Quality Carbide Long Neck is a premium machining tool engineered for demanding deep-cavity and hard-to-reach machining tasks. Crafted from industrial-grade tungsten carbide, this tool stands out for its unique long neck design that balances rigidity and accessibility, making it a top choice for manufacturers in mold making, aerospace component production, and precision engineering. Unlike conventional short-neck tools, the BFL Carbide Long Neck eliminates the need for multiple tool changes during deep-cavity operations, boosting productivity while maintaining uncompromised precision.

Core Application Scenarios

Ideal for precision machining of complex workpieces, this tool excels in scenarios such as deep pocket milling, mold cavity machining, and machining of parts with intricate internal structures. It is compatible with a wide range of materials, including high-hardness steel, stainless steel, titanium alloys, and engineering plastics, making it versatile across industries from automotive to medical device manufacturing.

Key Features & Benefits

Material

High-Grade Tungsten Carbide Composition

At the core of the BFL Carbide Long Neck is high-grade tungsten carbide – a material renowned for its exceptional hardness (HRC 90+) and wear resistance. This composition ensures the tool can withstand high cutting temperatures and intense pressure, outperforming HSS tools by 3-5 times in service life. The uniform grain structure of the carbide also enhances stability, preventing tool failure during prolonged machining sessions.

Corrosion & Wear Resistance

The tool’s surface is treated with a protective coating (optional TiN, TiAlN, or AlCrN) that adds an extra layer of corrosion resistance and reduces friction between the tool and workpiece. This not only extends tool life but also improves surface finish quality of the machined parts, minimizing the need for post-processing.

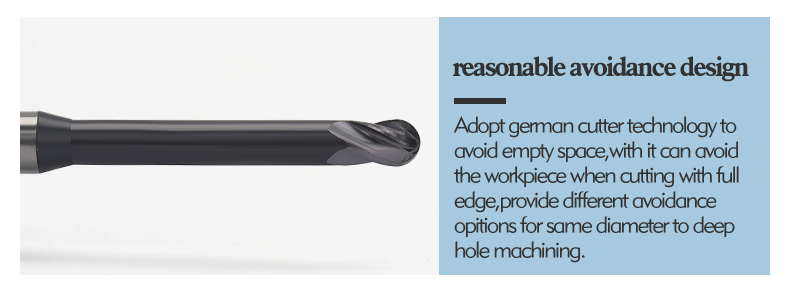

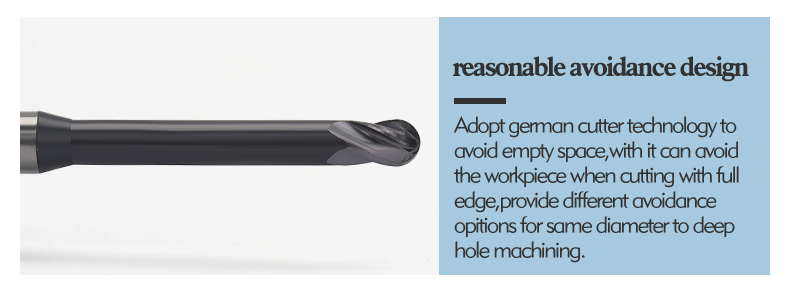

Ergonomic Long Neck Design

Extended Neck Length for Deep-Cavity Access

With a customizable neck length ranging from 50mm to 200mm, the BFL Carbide Long Neck easily reaches deep cavities and recesses that standard tools cannot access. This design eliminates the risk of tool collision with workpiece walls, ensuring safe and efficient machining of complex molds and components.

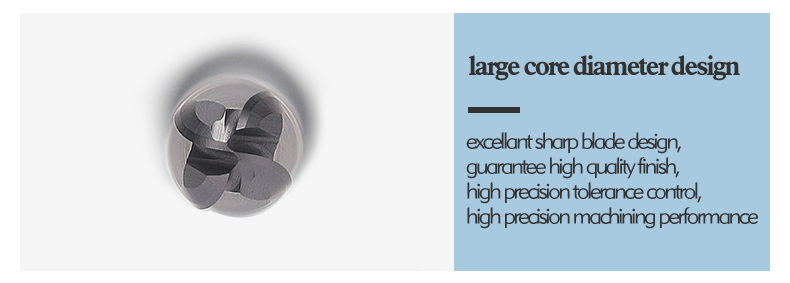

Rigid Structure to Prevent Vibration

Despite its extended neck, the tool features a reinforced shank and neck junction that enhances rigidity. This reduces machining vibration – a common issue in long-neck tools – which can cause poor surface finish and tool damage. The rigid structure ensures stable cutting even at high spindle speeds, delivering consistent results batch after batch.

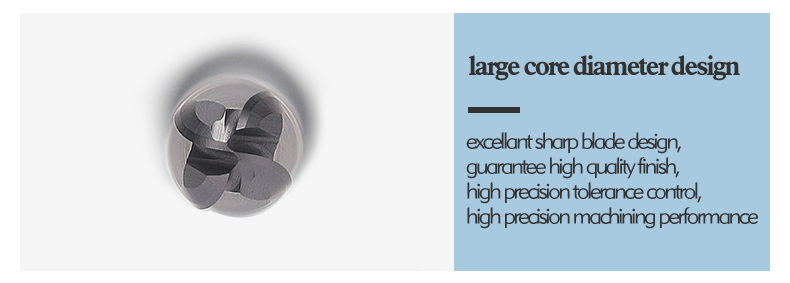

Precision-Centric Performance

Tight Tolerance Control (±0.002mm)

Every BFL Carbide Long Neck undergoes strict quality control to achieve a tolerance of ±0.002mm. This high precision ensures that the tool maintains accuracy even in high-volume production, meeting the strict requirements of industries like aerospace and medical manufacturing where dimensional accuracy is critical.

Consistent Cutting Results Across Batches

The combination of premium material, rigid design, and precise manufacturing ensures that each tool performs identically. This consistency reduces scrap rates and rework, lowering production costs for manufacturers while maintaining product quality.

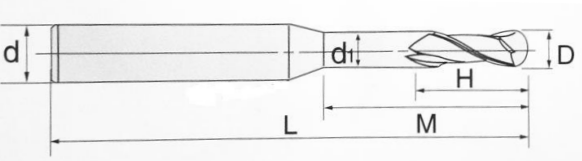

Product Specifications

Parameter | Details |

Neck Length | 50mm-200mm (customizable) |

Shank Diameter | 3mm-20mm (standard & custom sizes) |

Overall Length | 100mm-300mm (matches neck length) |

Tolerance | ±0.002mm |

Material | High-grade tungsten carbide |

Coating Option | TiN, TiAlN, AlCrN (customizable thickness) |

Applicable Materials | High-hardness steel, stainless steel, titanium alloys, engineering plastics |

Working Temperature Range | Up to 800℃ |

BFL OEM & Customization Services

Size Customization

Neck Length Adjustment (50mm-200mm)

Whether you need a 60mm neck for shallow cavities or a 180mm neck for deep molds, BFL offers precise neck length customization to match your specific machining needs. Our engineering team works closely with you to determine the optimal length for maximum performance.

Shank Diameter Tailoring (3mm-20mm)

We provide shank diameter customization from 3mm to 20mm, ensuring compatibility with your existing CNC machines, milling centers, or lathes. Standard shank types (straight, tapered) are available, and custom shank designs can be accommodated for special applications.

Coating Customization

TiN、TiAlN、AlCrN Coating Options

Choose from three high-performance coatings: TiN (for general-purpose machining), TiAlN (for high-temperature applications), or AlCrN (for extreme wear resistance). Each coating is applied using advanced PVD technology to ensure uniform coverage and adhesion.

Custom Coating Thickness (2μm-5μm)

Adjust the coating thickness between 2μm and 5μm based on your machining requirements. Thicker coatings (4-5μm) are ideal for heavy-duty cutting, while thinner coatings (2-3μm) suit precision finishing tasks.

Logo & Packaging Customization

Brand Logo Engraving

Add your brand logo or part number to the tool’s shank for easy identification and branding. We use laser engraving technology that ensures the logo remains legible even after prolonged use.

Customized Packaging for Bulk Orders

For bulk orders, we offer customized packaging options such as branded boxes, anti-rust packaging, or individual tool cases to protect the tools during transportation and storage. We can also include product manuals or quality certificates with your branding.

FAQ

What machining processes is the BFL Carbide Long Neck suitable for?

The tool is primarily designed for deep-cavity milling, pocket machining, and internal contouring. It is also suitable for semi-finishing and finishing operations where precision and accessibility are key.

Can it work with high-hardness materials like stainless steel?

Yes. The high-grade tungsten carbide material and optional AlCrN coating make the tool ideal for machining high-hardness materials (up to HRC 60), including stainless steel, Inconel, and hardened steel.

What is the typical service life of this tool?

Under normal operating conditions, the BFL Carbide Long Neck has a service life 3-5 times longer than HSS tools. For high-hardness materials, the service life may vary based on cutting speed and feed rate, but our tools consistently outperform industry standards.

How long does the OEM customization take?

Standard customization (size, coating) takes 7-10 business days. For complex custom designs (e.g., unique shank shapes, special coatings), the lead time is 12-15 business days. We offer expedited production for urgent orders (additional fees apply).

Is technical support available for tool selection?

Absolutely. Our team of machining experts provides free technical support to help you select the right neck length, coating, and size for your application. We can also offer cutting parameter recommendations (speed, feed rate) to optimize tool performance.

English

English