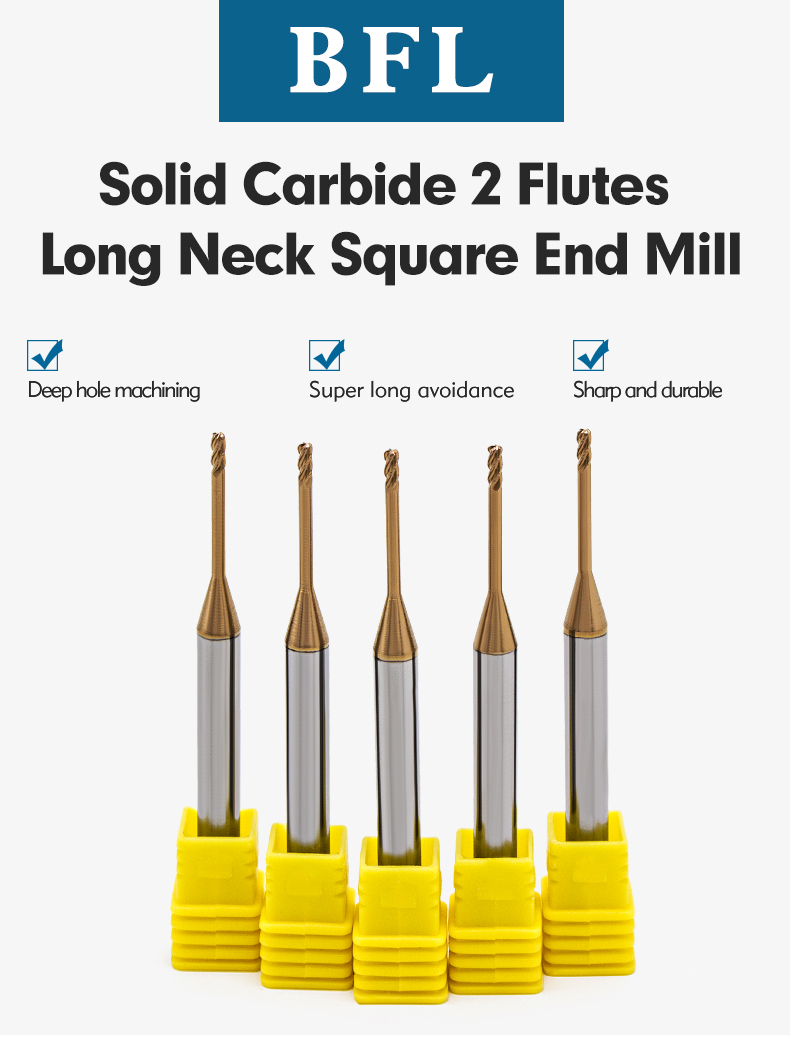

Product Overview

This endmill is tailored for industries such as automotive parts manufacturing, electronic component production, furniture making, and precision engineering. Key applications include slot milling, face milling, contour milling, and profiling of materials like aluminum, steel, copper, wood, and composite materials. Its 16mm diameter makes it ideal for medium-sized workpieces where balance between material removal rate and precision is essential.

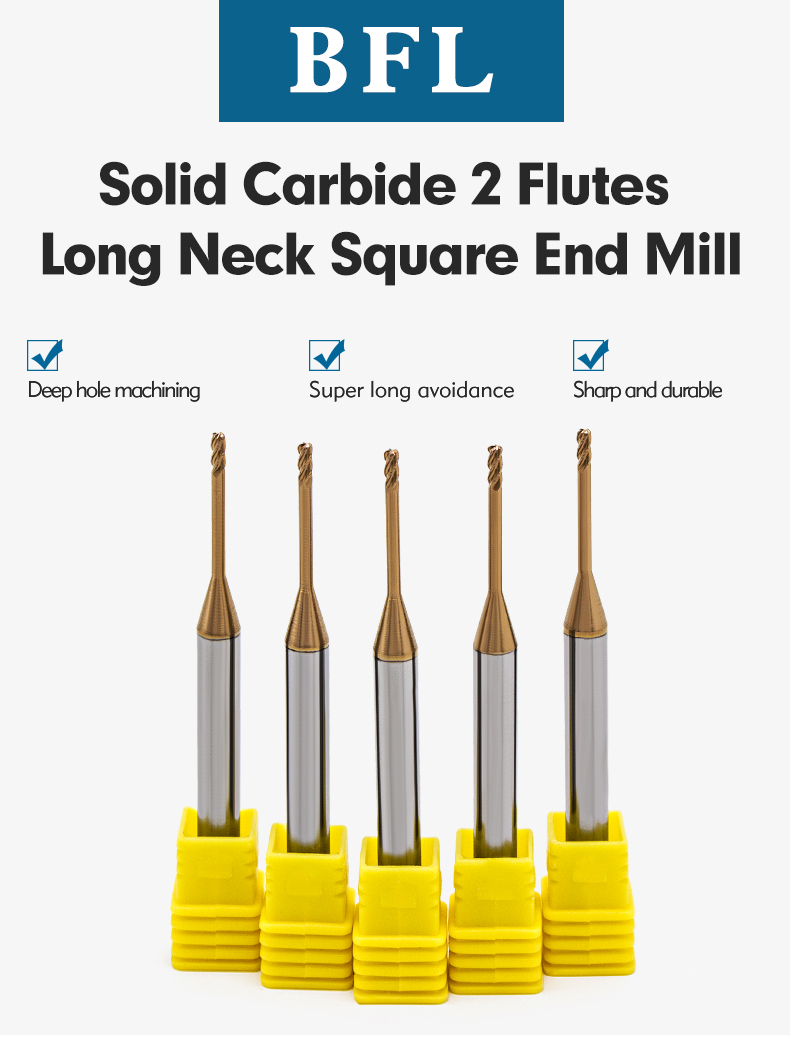

Key Features & Benefits

Single-Piece Solid Carbide Construction

Uniform Material Density for Enhanced Strength

Unlike brazed or assembled endmills, the BFL Solid Carbide Endmill 16 is machined from a single block of high-purity tungsten carbide, ensuring uniform density throughout the tool. This eliminates structural weaknesses (e.g., brazed joints) that can lead to tool breakage under high loads, making it suitable for heavy-duty machining.

Shatter-Resistant Design for Heavy-Duty Milling

The solid carbide structure is engineered to withstand impact and vibration during aggressive cutting. Its shatter-resistant properties reduce downtime caused by tool failure, while the material’s high stiffness minimizes deflection, ensuring accurate cuts even at high feed rates.

16mm Optimized Diameter

Perfect for Medium-Sized Milling Tasks

The 16mm diameter is optimized for medium-scale milling operations, striking a balance between material removal rate and precision. It can quickly remove material during roughing while maintaining tight tolerances during finishing, reducing the need for multiple tool changes.

Compatibility with Standard & CNC Machines

The 16mm diameter is compatible with most standard milling machines, CNC machining centers, and vertical/horizontal mills. Its standard shank (typically 16mm or 20mm) ensures easy installation, making it a drop-in replacement for existing tools in your workshop.

Advanced Cutting Edge Technology

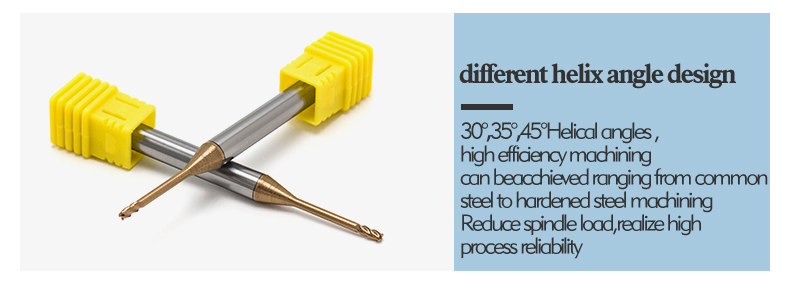

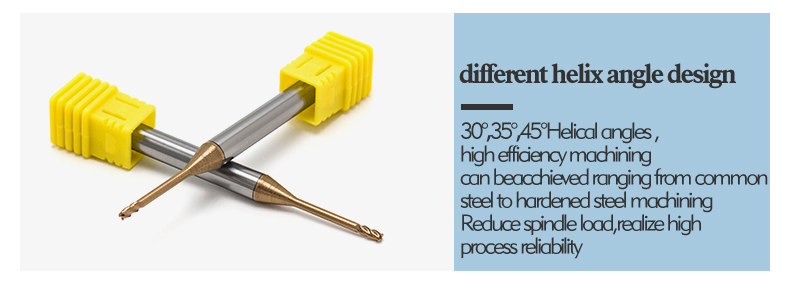

Helical Flute Design for Smooth Chip Evacuation

Equipped with 2-6 helical flutes (customizable), the endmill features an optimized helix angle (30°-45°) that facilitates smooth chip evacuation. This prevents chip clogging – a common issue in milling – which can damage the tool and workpiece. The helical design also reduces cutting force, improving surface finish quality.

Sharpened Edge for Reduced Cutting Force

The cutting edges are precision-sharpened using advanced grinding technology, ensuring a keen edge that minimizes cutting force. This not only reduces tool wear but also lowers energy consumption and extends the life of your machining equipment. For high-adhesion materials like aluminum, optional edge honing is available to prevent built-up edge (BUE).

Product Specifications

Parameter | Details |

Diameter | 16mm (fixed core size) |

Flute Count | 2/3/4/6 (customizable) |

Flute Length | 30mm-80mm (matches application needs) |

Overall Length | 70mm-150mm (varies by flute length) |

Spiral Angle | 30°-45° (optimized for chip evacuation) |

Tolerance | h6 (±0.011mm) |

Material | Single-piece solid tungsten carbide |

Coating | TiN, TiAlN, Diamond-Like Carbon (DLC) |

Max Cutting Speed | 300m/min (steel), 1500m/min (aluminum) |

Applicable Materials | Aluminum, steel, copper, wood, composite materials, mild steel |

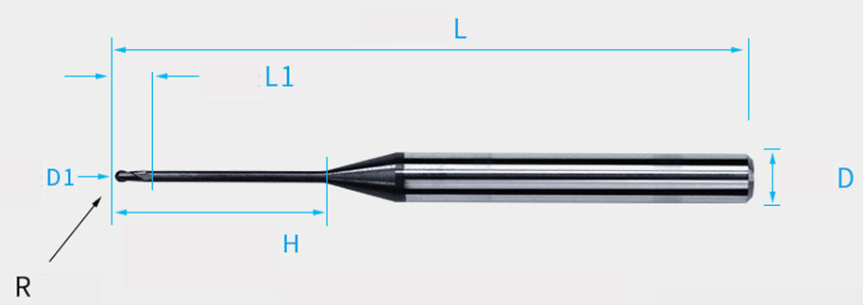

Project code | Outer diameter | Flute length | Effective length | Total length | Handle diameter |

BFL-BD-004-02 | 0.4 | 0.6 | 2 | 50 | 4 |

BFL-BD-005-06 | 0.5 | 0.8 | 6 | 50 | 4 |

BFL-BD-006-06 | 0.6 | 1.0 | 6 | 50 | 4 |

BFL-BD-008-10 | 0.8 | 1.2 | 10 | 50 | 4 |

BFL-BD-010-12 | 1.0 | 1.2 | 12 | 50 | 4 |

BFL-BD-015-12 | 1.5 | 1.7 | 12 | 50 | 4 |

BFL-BD-020-16 | 2.0 | 2.2 | 16 | 50 | 4 |

BFL OEM & Customization Services

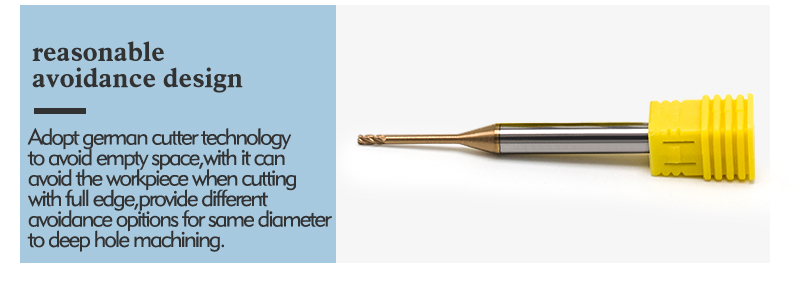

Flute Count Customization (2/3/4/6 Flutes)

Choose the number of flutes based on your machining needs: 2 flutes for high-speed cutting of aluminum, 4 flutes for general-purpose steel machining, 6 flutes for precision finishing. Our engineering team can recommend the optimal flute count based on your workpiece material and machining process.

Cutting Edge Treatment (Polished/Coated/Honed)

Customize the cutting edge treatment to enhance performance for specific materials:

Polished edges: Reduce friction for aluminum and non-ferrous metals.

Coated edges: TiAlN or DLC coating for high-temperature and high-wear applications.

Honed edges: Prevent BUE for sticky materials like stainless steel and copper.

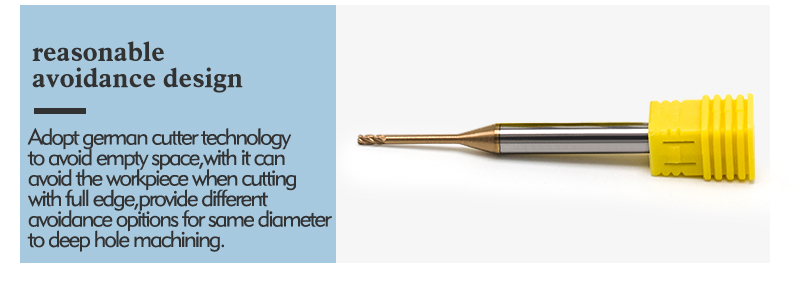

Dimensional Tailoring (Flute Length/Overall Length)

Adjust the flute length (30mm-80mm) and overall length (70mm-150mm) to match your workpiece dimensions. Longer flute lengths are ideal for deep slot milling, while shorter lengths offer better rigidity for high-precision finishing.

Branding & Packaging Solutions

Logo Engraving: Laser-engrave your brand logo, part number, or batch code on the shank for easy tracking and branding.

Custom Packaging: For bulk orders, we offer branded boxes, anti-corrosion packaging, or individual tool sleeves. We can also include custom instruction manuals or quality inspection reports.

FAQ

What is the advantage of the 16mm diameter in milling?

The 16mm diameter is a versatile size that balances material removal rate and precision. It can remove more material than smaller diameters (e.g., 10mm) during roughing while maintaining the accuracy needed for finishing. It’s also compatible with most standard milling setups, making it a cost-effective choice for medium-sized workpieces.

Can this endmill be used for both roughing and finishing?

Yes. The BFL Solid Carbide Endmill 16 is designed for multi-process machining. With 2-3 flutes, it excels in roughing (high material removal rate), while 4-6 flutes deliver smooth finishing results. Simply adjust cutting parameters (speed, feed rate) to switch between processes, reducing tool change time.

What coating option is best for aluminum machining?

For aluminum, we recommend the DLC coating or polished edges (no coating). DLC reduces friction and prevents chip adhesion, while polished edges eliminate built-up edge (BUE) – a common problem when machining soft metals like aluminum.

How to maintain the BFL Solid Carbide Endmill 16 for longer life?

To extend tool life: (1) Use proper cutting fluids to cool the tool and workpiece; (2) Avoid exceeding the maximum cutting speed and feed rate; (3) Clean the tool after use to remove chips and debris; (4) Store in a dry, anti-rust environment. Regular inspection of cutting edges for wear is also recommended.

Do you provide sample testing before bulk orders?

Yes. We offer free sample testing for qualified customers. You can test the BFL Solid Carbide Endmill 16 in your actual machining environment to verify performance, precision, and compatibility before placing a bulk order. Our team provides technical support during testing to ensure optimal results.

English

English