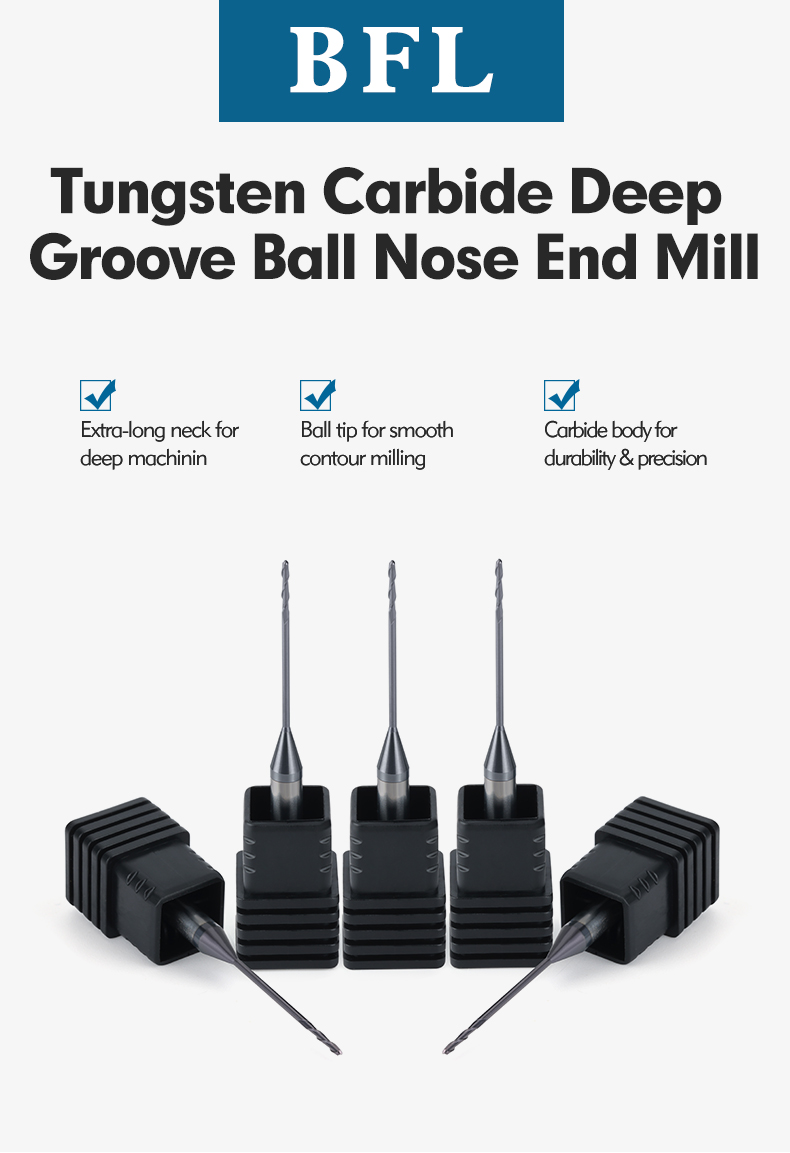

Product Overview

Crafted from top-grade tungsten carbide, this tool distinguishes itself with an innovative long neck design—a core advantage that enables access to hard-to-reach areas in complex workpieces without sacrificing rigidity or cutting performance. Suitable for both high-speed machining (HSM) and conventional milling, the BFL Carbide Long Neck delivers exceptional durability, precision, and efficiency, making it a trusted choice for manufacturers aiming to optimize production workflows and reduce tool wear. Whether processing steel, aluminum, titanium alloys, or composite materials, this carbide machining tool ensures consistent results, even under high-temperature and high-pressure operating conditions.

Key Features & Benefits

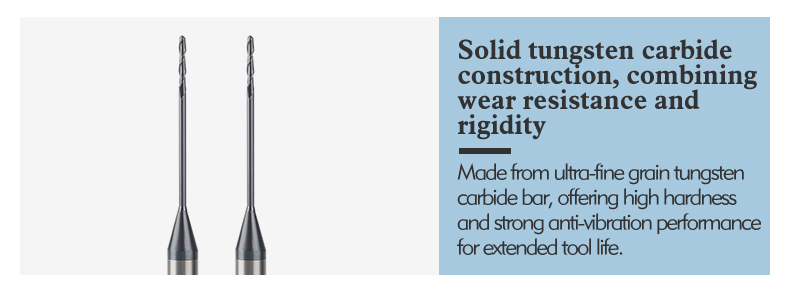

Material: Premium Tungsten Carbide Composition

High-Purity Carbide Base

The BFL Carbide Long Neck is forged from high-purity tungsten carbide—a material celebrated for its extraordinary hardness (up to HRA 92.5) and wear resistance. Unlike standard carbide tools, our product adopts a fine-grain carbide matrix that minimizes chipping and extends tool life by up to 300% compared to HSS alternatives.

Corrosion & Heat Resistance

Infused with advanced additives, the carbide material exhibits superior heat resistance (operating temperature up to 1200°C) and corrosion resistance, making it suitable for both wet and dry machining. This feature eliminates tool degradation caused by coolant chemicals or high friction, ensuring stable performance during long production runs.

Ergonomic Long Neck Design

Extended Reach for Complex Workpieces

The precision-engineered long neck (available in lengths from 50mm to 200mm) provides unmatched access to deep cavities, narrow slots, and recessed areas in molds, dies, and aerospace components. This design eliminates the need for specialized adapters, reducing setup time and improving machining accuracy.

Rigidity Optimization

Despite its extended length, the long neck is reinforced with a tapered core design that enhances structural rigidity. This minimizes vibration during high-speed cutting, reducing surface roughness (Ra ≤ 0.8μm) and ensuring tight dimensional tolerances (±0.005mm).

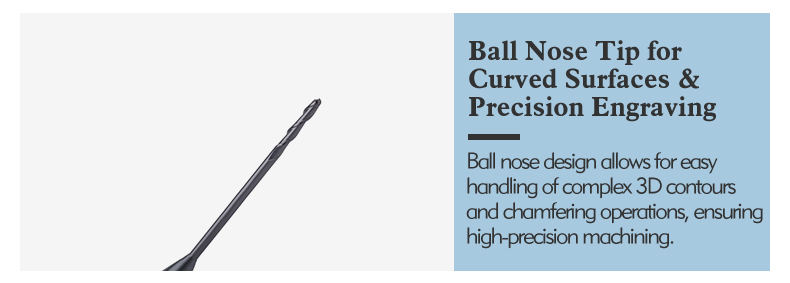

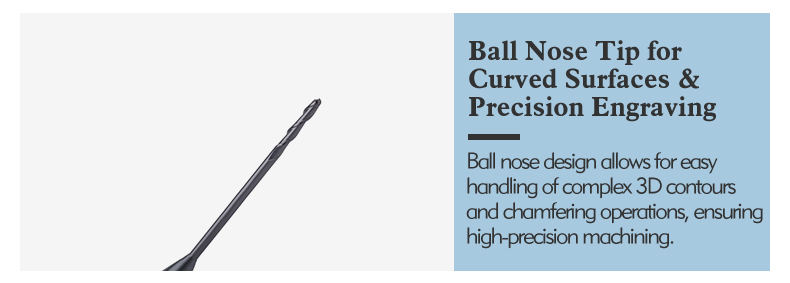

Precision Cutting Edge

Sharpened & Polished Flutes

Each BFL Carbide Long Neck features precision-sharpened flutes with a polished surface finish. The sharp cutting edges reduce cutting forces, lower energy consumption, and produce smooth workpiece surfaces—eliminating the need for secondary finishing operations.

Customizable Flute Count

Available in 2-flute, 4-flute, and 6-flute configurations, the tool can be tailored to specific materials: 2-flute for aluminum and non-ferrous metals (optimized for chip evacuation), 4-flute for steel and stainless steel (balanced cutting force), and 6-flute for high-precision finishing.

Product Specifications

Specification Category | Details |

Material | High-purity tungsten carbide (WC-Co) |

Neck Length | 50mm, 80mm, 100mm, 150mm, 200mm (customizable) |

Shank Diameter | 6mm, 8mm, 10mm, 12mm, 16mm (metric) |

Cutting Edge Diameter | 4mm-16mm (metric, ±0.003mm tolerance) |

Flute Count | 2, 4, 6 (customizable) |

Operating Temperature | Up to 1200°C |

Tolerance Grade | IT3-IT5 |

Applicable Materials | Steel, stainless steel, aluminum, titanium alloys, composites, plastics |

Machining Type | Milling, slotting, profiling, cavity machining |

BFL OEM & Customization Services

Custom Dimension Tailoring

Neck & Shank Size Adjustment

BFL offers full dimension customization for the Carbide Long Neck tool. Whether you need a specific neck length (e.g., 75mm for niche mold applications) or a non-standard shank diameter (e.g., 14mm), our engineering team collaborates closely with you to design tools that fit your exact machining requirements.

Cutting Edge Customization

Adjust the cutting edge diameter, flute angle (25°, 30°, 45°), or helix direction (right-hand, left-hand) to optimize performance for your target materials. For example, a 45° helix angle is available for high-speed machining of stainless steel.

Material Grade & Coating Options

Carbide Grade Selection

Choose from a range of carbide grades to match your application: Grade YG6X (for non-ferrous metals), Grade YT15 (for steel), and Grade YW2 (for multi-material machining). For extreme conditions, we offer premium grades with enhanced toughness and wear resistance.

Protective Coatings

Select from TiN (titanium nitride), TiAlN (titanium aluminum nitride), or DLC (diamond-like carbon) coatings. TiAlN coating, for instance, boosts heat resistance and reduces friction, extending tool life by 200% in high-temperature machining.

Branding & Packaging Solutions

OEM Branding

Add your company logo, part number, or technical specifications to the tool shank via laser engraving—perfect for building brand recognition in the industrial market.

Custom Packaging

We provide tailored packaging options, including blister packs, cardboard boxes, or bulk containers, with your branding and usage instructions. This ensures safe transportation and enhances the professional appearance of your product line.

FAQ

What makes the BFL Carbide Long Neck different from standard carbide tools?

The BFL High-Quality Carbide Long Neck combines premium high-purity carbide material with a rigid, extended neck design—enabling access to hard-to-reach areas while maintaining precision. Unlike standard tools, it offers customizable flute counts, coating options, and dimension adjustments, making it versatile for diverse industrial applications. Its superior heat and wear resistance also ensures longer tool life and consistent performance.

Can this tool be used for titanium alloy machining?

Yes! The BFL Carbide Long Neck is optimized for titanium alloy machining when paired with the YW2 carbide grade and TiAlN coating. The sharp cutting edges reduce cutting forces, while the heat-resistant material prevents tool deformation—delivering smooth, accurate results even with this challenging material.

What is the lead time for custom OEM orders?

Standard custom orders (dimension adjustments, coating changes) have a lead time of 7-10 business days. For complex customizations (unique carbide grades, specialized flute designs), lead time may extend to 15-20 business days. We offer expedited production options for urgent orders (additional fees apply).

How should I maintain the BFL Carbide Long Neck to maximize its lifespan?

To extend tool life, avoid overloading the cutting edge (follow recommended cutting speeds and feeds), use appropriate coolants for high-temperature applications, and store the tool in a dry, dust-free environment. Regularly inspect the cutting edge for chipping or wear—replace the tool if damage is detected to prevent workpiece defects.

Does BFL provide technical support for tool selection?

Absolutely! Our team of machining experts offers free technical support to help you select the right flute count, carbide grade, and coating for your specific application. We can also provide cutting parameter recommendations (speed, feed rate, depth of cut) to optimize performance and reduce production costs.

English

English